Top Elcometer 3086 Motorised Pencil Hardness Tester, Data sheet elcometer 3086 motorised pencil hardness tester elcometer 3086 motorised pencil hardness tester similar to the elcometer 501 and using the same pencil technique this motorised device in anodised aluminium can travel forwards chip method or backwards indentation method at a uniform speed further increasing the.

Elcometer 3086 motorised pencil hardness tester.

The elcometer 3086 motorised pencil hardness tester using the same test methods and principles as the elcometer 501 pencil hardness tester removes both of these variables by being fully independent.

In this video learn how to prepare and use the elcometer 3086 motorized pencil hardness tester to evaluate a coatings hardness and adhesion to a substrate.

The uniformity of the carriage speed and the variation of the applied force by the user as the manual tester is moved across the coating.

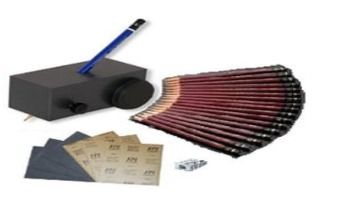

Elcometer 501 pencil hardness tester the pencil hardness test also referred to as the wolff wilborn test uses the varying hardness values of graphite pencils to evaluate a coatings hardness.

The elcometer 3086 motorised pencil hardness tester using the same test methods and principles as the elcometer 501 pencil hardness tester removes both of these variables by being fully independent.

In this video learn how to prepare and use the elcometer 3086 motorized pencil hardness tester to evaluate a coatings hardness and adhesion to a substrate.

The uniformity of the carriage speed and the variation of the applied force by the user as the manual tester is moved across the coating.

Elcometer 501 pencil hardness tester the pencil hardness test also referred to as the wolff wilborn test uses the varying hardness values of graphite pencils to evaluate a coatings hardness.

Elcometer 3086 motorised pencil hardness tester discontinued discontinued product for servicing use only traditional pencil hardness testers can be limited in their reproducibility and repeatability by two key factors.

This test is known as the wolff wilborn method and is fully described in bs 3900 e19 iso 15184 and astm d 3363 92a.

Elcometer 3086 motorised pencil hardness tester provides a rapid method for determination of the comparative scratch resistance and hardness of a coating.

Suppliers and manufacturers of elcometer 3086 motorised pensil hardness tester chennaithe internal motor drives the unit at a constant uniform speed across the coated surface exerting a fixed user determined force between 0 to 10n.

Elcometer 3086 motorised pencil hardness tester discontinued discontinued product for servicing use only traditional pencil hardness testers can be limited in their reproducibility and repeatability by two key factors.

This test is known as the wolff wilborn method and is fully described in bs 3900 e19 iso 15184 and astm d 3363 92a.

Elcometer 3086 motorised pencil hardness tester provides a rapid method for determination of the comparative scratch resistance and hardness of a coating.

Suppliers and manufacturers of elcometer 3086 motorised pensil hardness tester chennaithe internal motor drives the unit at a constant uniform speed across the coated surface exerting a fixed user determined force between 0 to 10n.

Category science technology.

This test is known as the wolff wilborn method and is fully described in bs 3900 e19 iso 15184 and astm d 3363 92aa coated panel is placed on a firm horizontal surface and the pencil lead is held firmly against the coating point way.

Category science technology.

This test is known as the wolff wilborn method and is fully described in bs 3900 e19 iso 15184 and astm d 3363 92aa coated panel is placed on a firm horizontal surface and the pencil lead is held firmly against the coating point way.