Top Hardness Shore D Meaning, Shore hardness definition is hardness of metal or other material as measured by a shore scleroscope.

Hardness shore d meaning.

For further information check out the material selection guide which provides a compound family overview including a description of compound advantages typical temperature maximumminimum compatible fluids and material durometers.

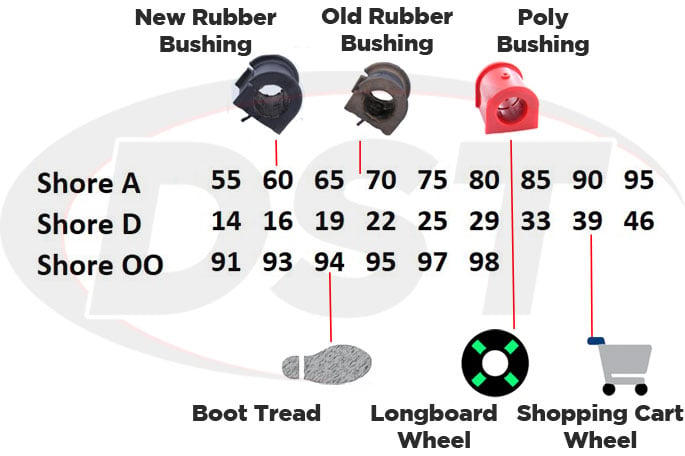

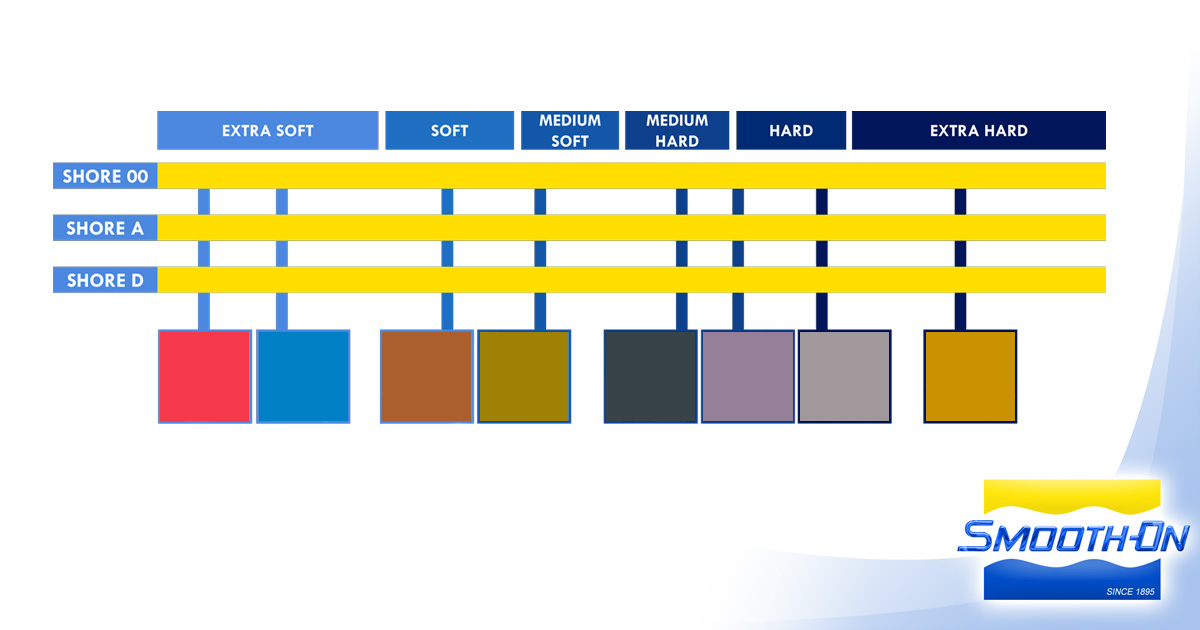

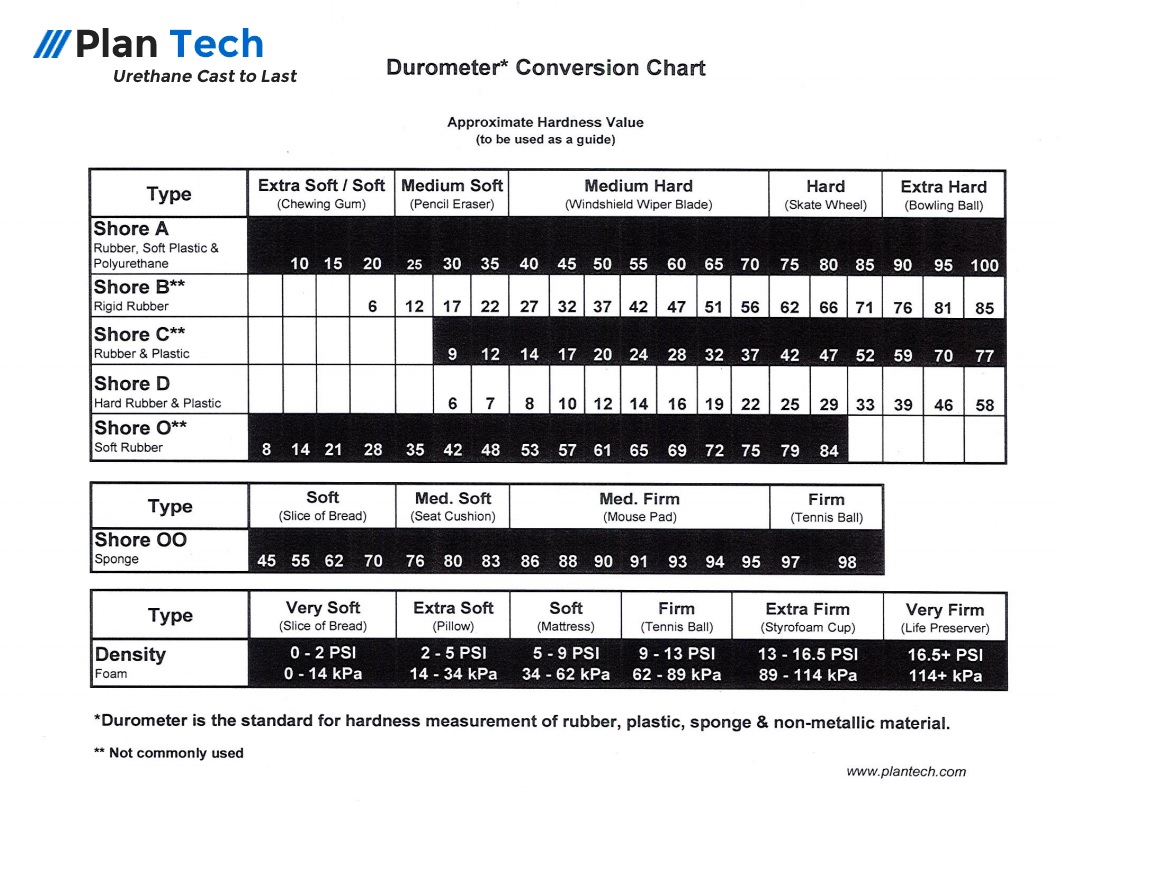

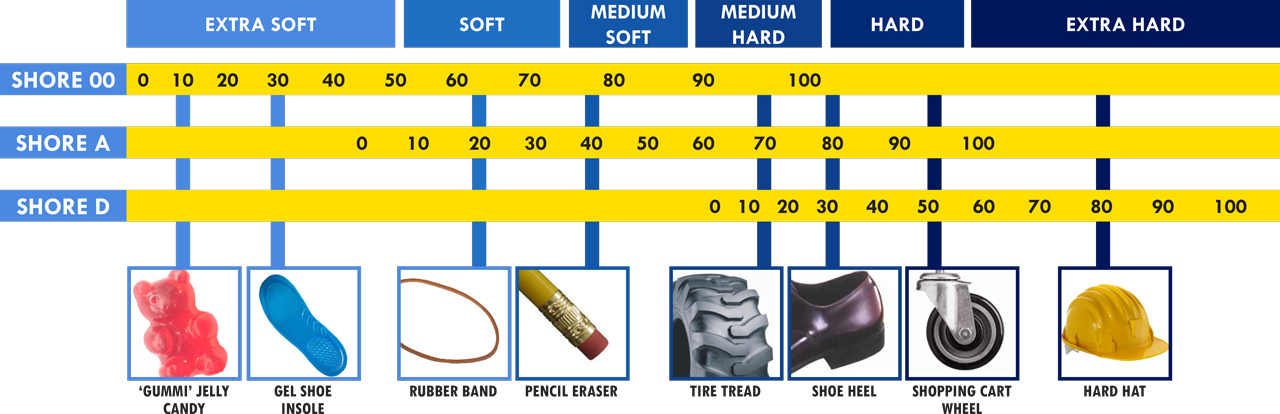

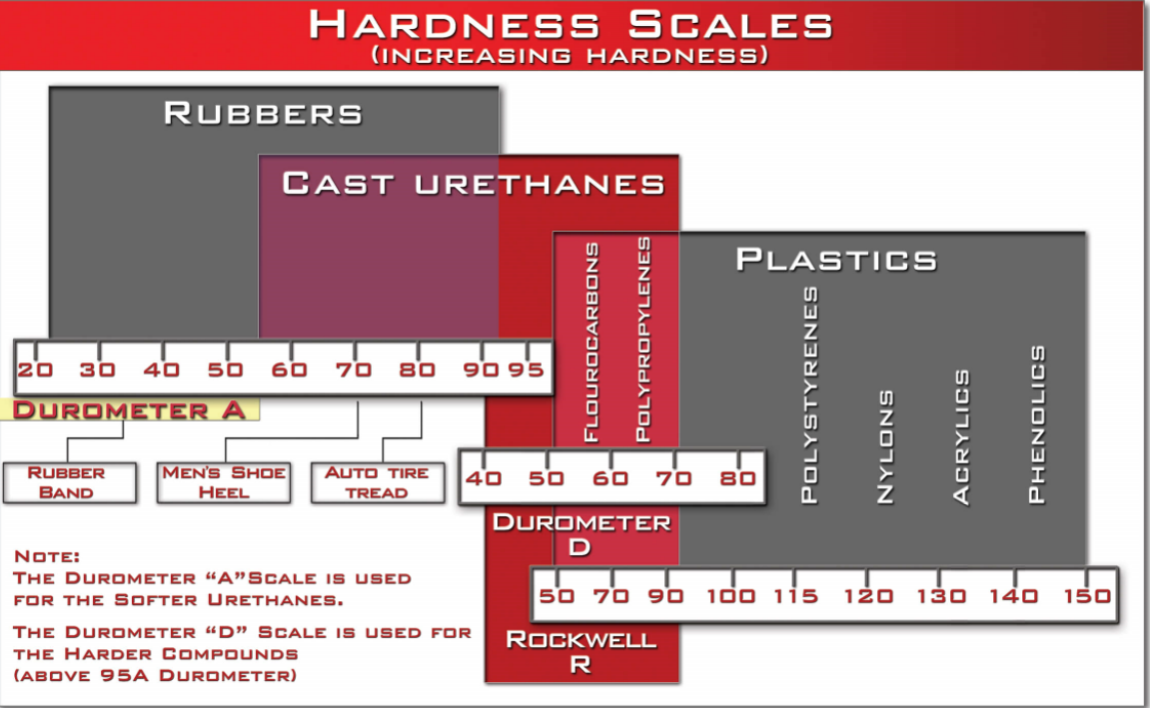

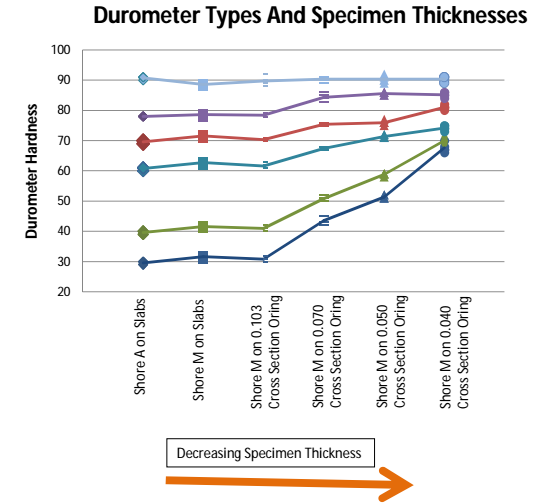

As you can see from the chart there is overlap on the different scales.

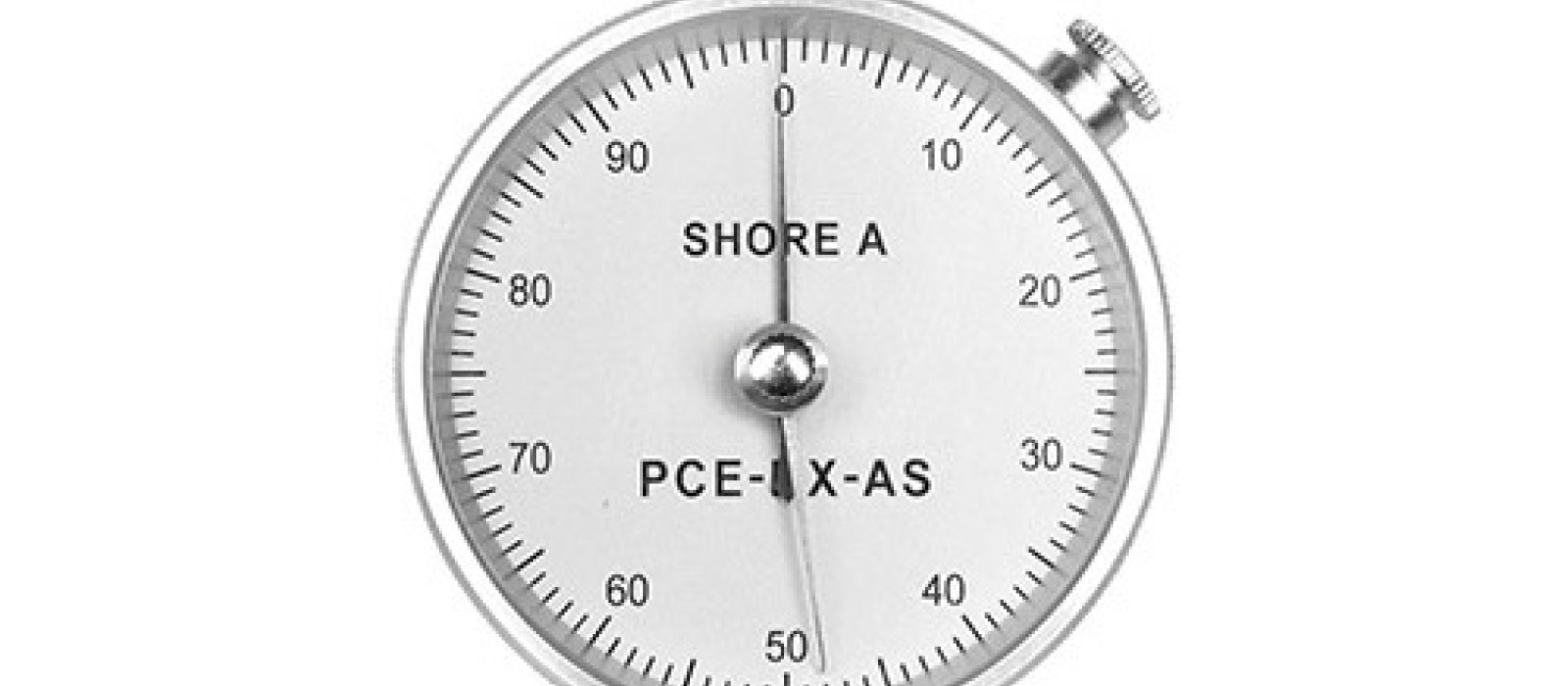

The shore a hardness scale measures the hardness of flexible mold rubbers that range in hardness from very soft and flexible to medium and somewhat flexible to hard with almost no flexibility at all.

With readings taken between 0 and 100 shore hardness measures are dimensionless.

For further information check out the material selection guide which provides a compound family overview including a description of compound advantages typical temperature maximumminimum compatible fluids and material durometers.

As you can see from the chart there is overlap on the different scales.

The shore a hardness scale measures the hardness of flexible mold rubbers that range in hardness from very soft and flexible to medium and somewhat flexible to hard with almost no flexibility at all.

With readings taken between 0 and 100 shore hardness measures are dimensionless.

Approximate hardness value to be used as a guide type extra soft soft chewing gum medium soft pencil eraser medium hard windshield wiper blade hard skate wheel extra hard bowling ball shore a rubber soft plastic polyurethane 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 shore b rigid rubber 6 12 17 22 27 32 37 42.

The tolerance on the shore a hardness is 5 for all parker compounds.

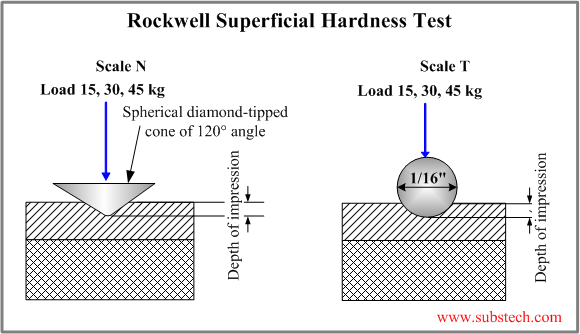

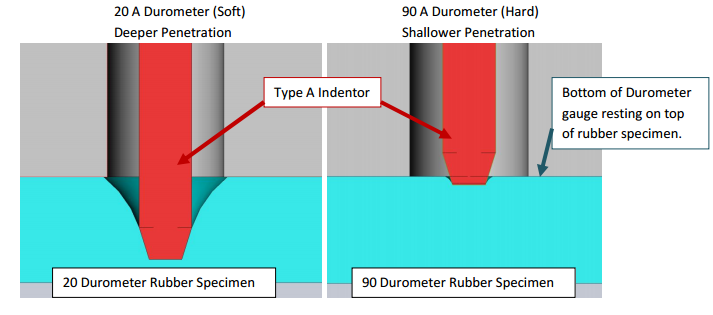

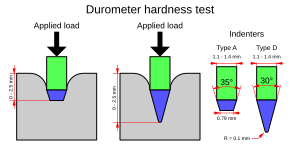

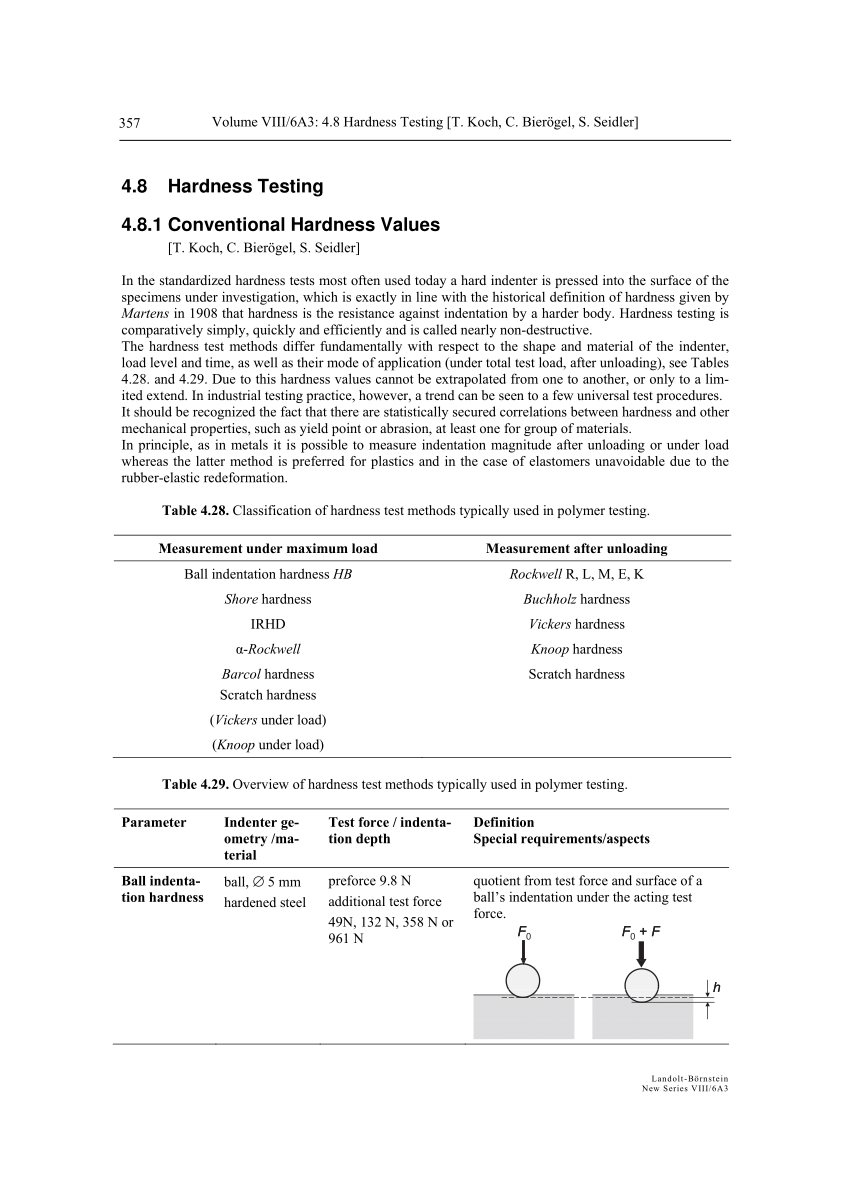

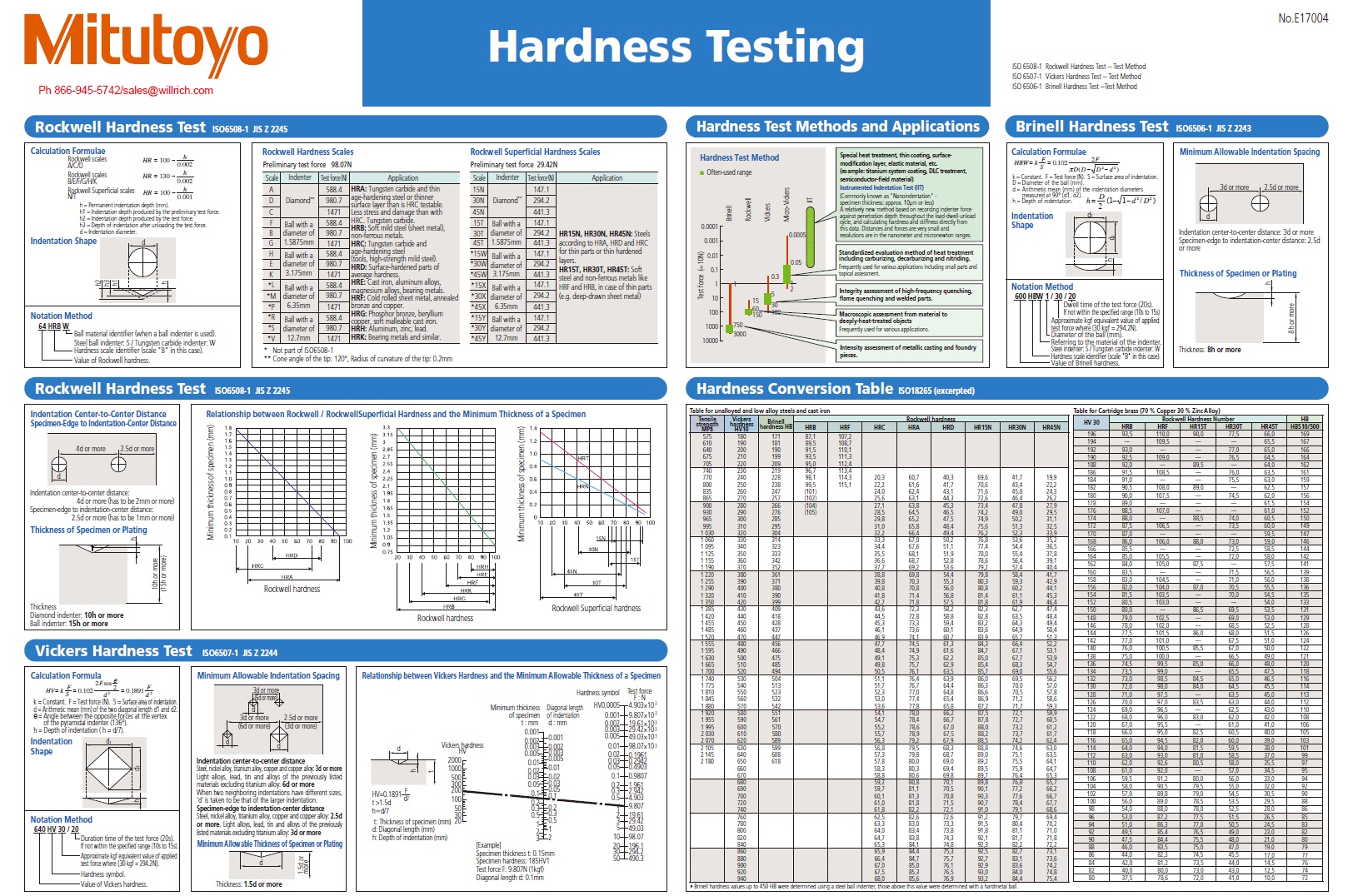

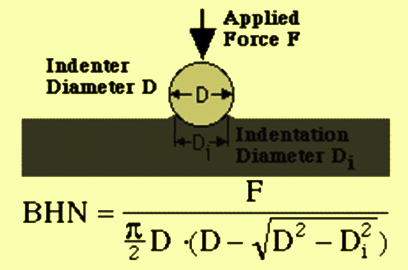

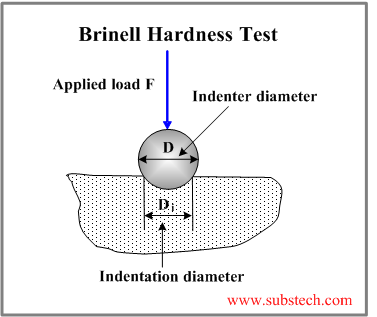

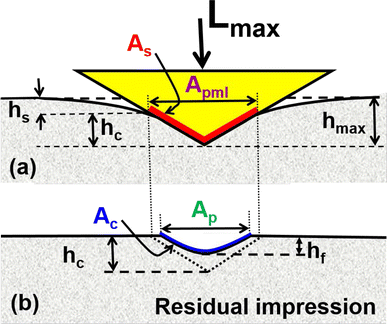

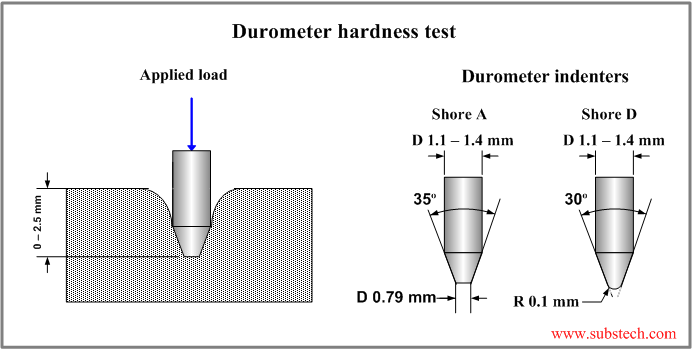

The measured hardness is determined by the penetration depth of the indenter under the load.

10 lb 4536 g.

Approximate hardness value to be used as a guide type extra soft soft chewing gum medium soft pencil eraser medium hard windshield wiper blade hard skate wheel extra hard bowling ball shore a rubber soft plastic polyurethane 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 shore b rigid rubber 6 12 17 22 27 32 37 42.

The tolerance on the shore a hardness is 5 for all parker compounds.

The measured hardness is determined by the penetration depth of the indenter under the load.

10 lb 4536 g.

For example a material with a shore hardness of 95a is also a shore 45d.

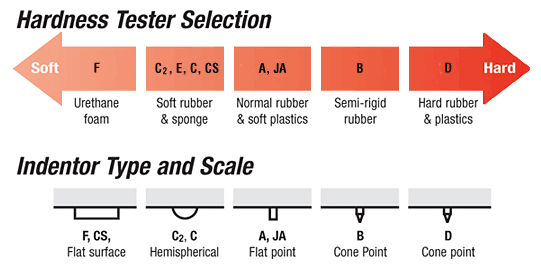

There are different shore hardness scales for measuring the hardness of different materials soft rubbers rigid plastics and supersoft gels for example.

Shore d hardness scale measures the hardness of hard rubbers semi rigid plastics and hard plastics.

Semi rigid plastics can also be measured on the high end of the shore a scale.

For example a material with a shore hardness of 95a is also a shore 45d.

There are different shore hardness scales for measuring the hardness of different materials soft rubbers rigid plastics and supersoft gels for example.

Shore d hardness scale measures the hardness of hard rubbers semi rigid plastics and hard plastics.

Semi rigid plastics can also be measured on the high end of the shore a scale.

These scales were invented so that people can discuss these materials and have a common point of reference.

Compound n0674 70 has a shore a hardness of 70 while nm304 75 has a shore a hardness of 75.

Lower numbers indicate less resistance and softer materials.

Semi rigid plastics can also be measured on the high end of the shore a scale.

These scales were invented so that people can discuss these materials and have a common point of reference.

Compound n0674 70 has a shore a hardness of 70 while nm304 75 has a shore a hardness of 75.

Lower numbers indicate less resistance and softer materials.

Semi rigid plastics can also be measured on the high end of the shore a scale.

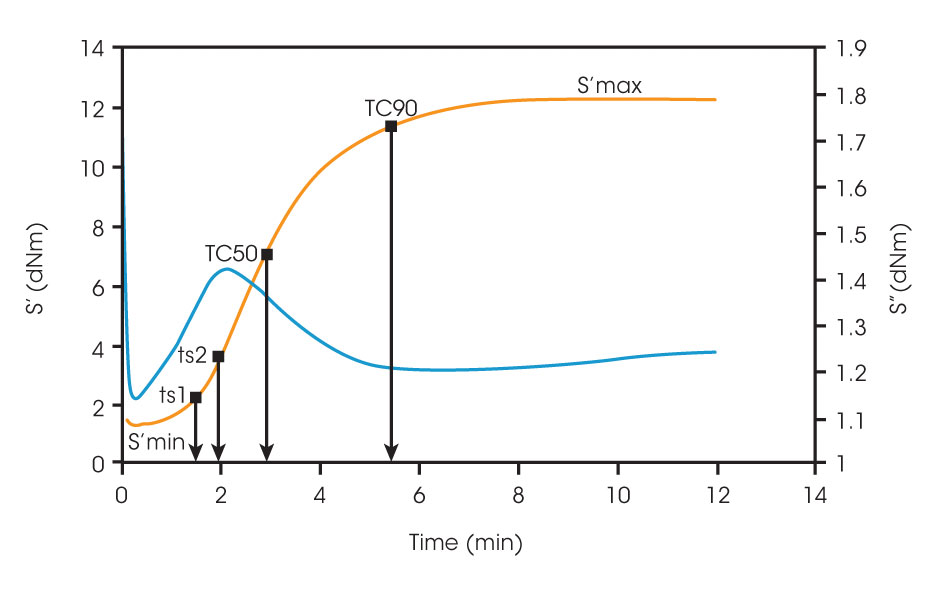

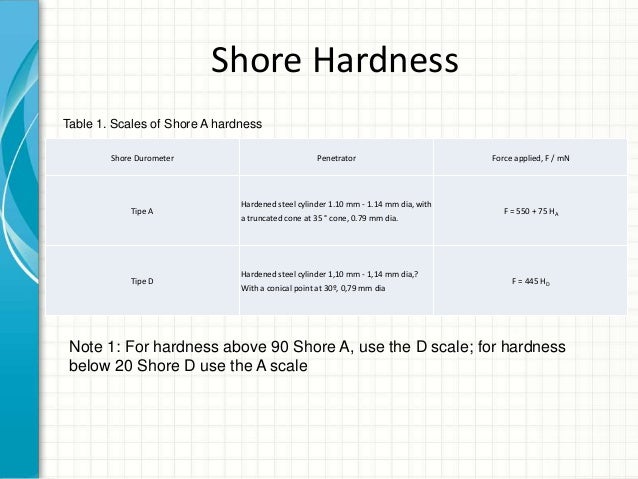

The loading forces of shore a.

Shore hardness value may vary in the range from 0 to 100.

1812 lb 822 g shore d.

While not needed for plaster casting shore hardness proves helpful when you have to choose your materials such as which silicone rubber should be used for making a mold or cast.

The loading forces of shore a.

Shore hardness value may vary in the range from 0 to 100.

1812 lb 822 g shore d.

While not needed for plaster casting shore hardness proves helpful when you have to choose your materials such as which silicone rubber should be used for making a mold or cast.

Shore d hardness scale is reserved for measuring the hardness of hard rubbers semi rigid plastics and hard plastics.

The shore d hardness scale measures the hardness of hard rubbers.

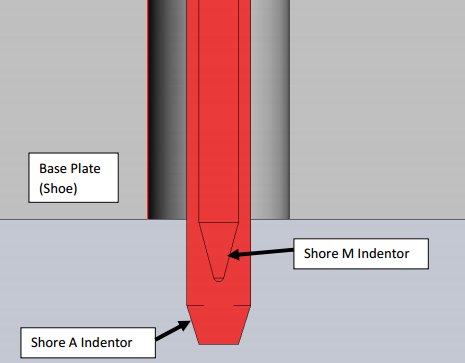

Two different indenter shapes see the picture below and two different spring loads are used for two shore scales a and d.

Shore hardness is a measure of the resistance a material has to indentation.

Shore d hardness scale is reserved for measuring the hardness of hard rubbers semi rigid plastics and hard plastics.

The shore d hardness scale measures the hardness of hard rubbers.

Two different indenter shapes see the picture below and two different spring loads are used for two shore scales a and d.

Shore hardness is a measure of the resistance a material has to indentation.