Top Polyurethane Hardness Shore A, Shore a 0 denotes extremely soft gel like materials such as silicones while semi rigid plastics will be measured at the highest end of the scale around 90 95a.

Polyurethane hardness shore a.

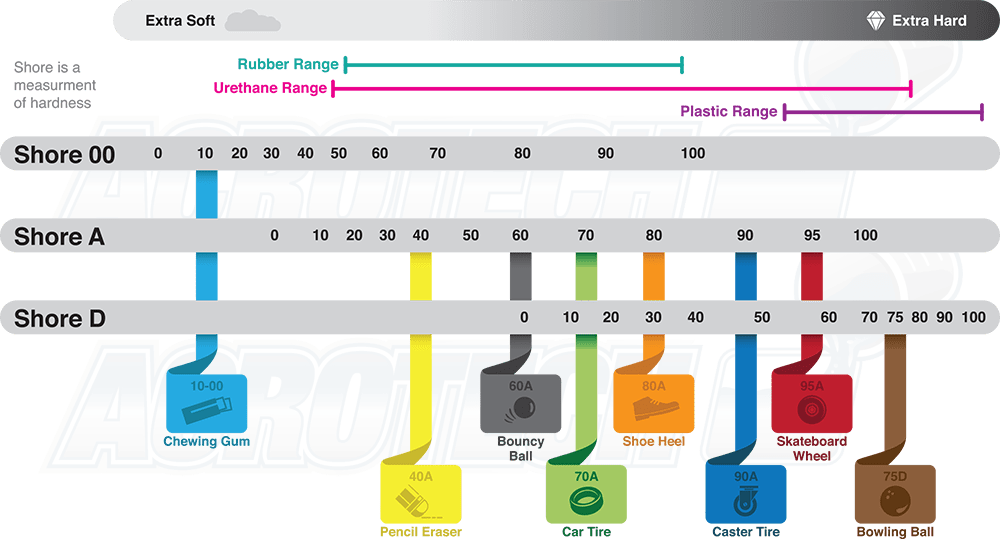

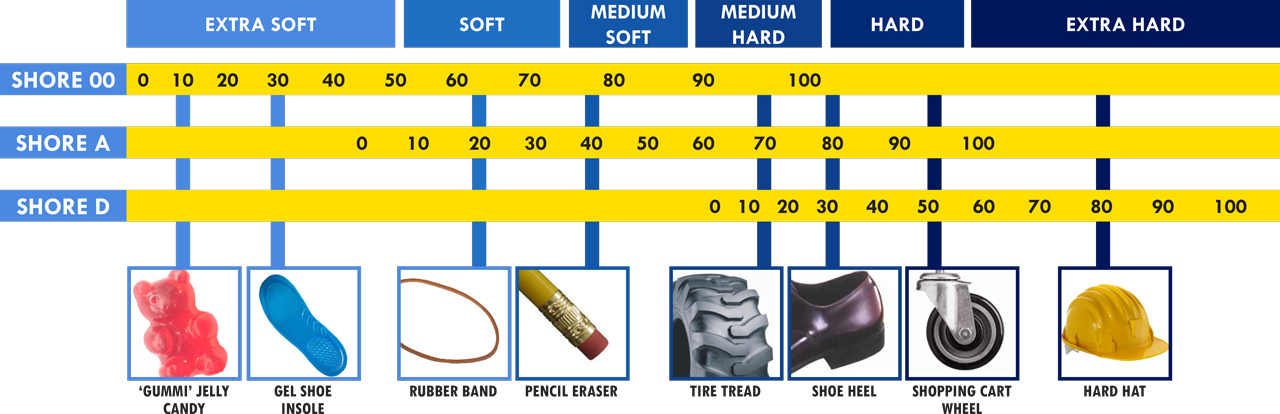

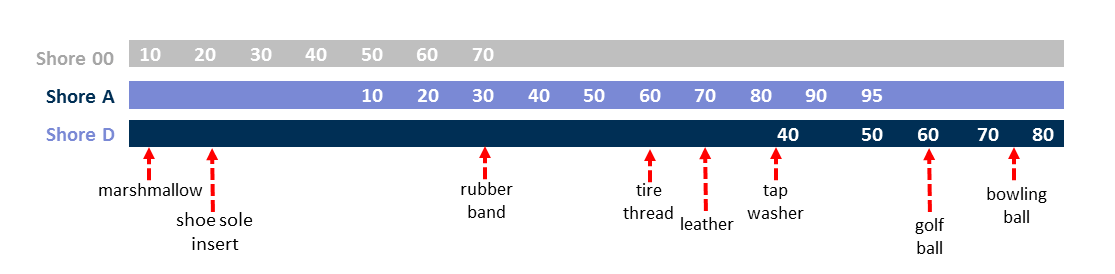

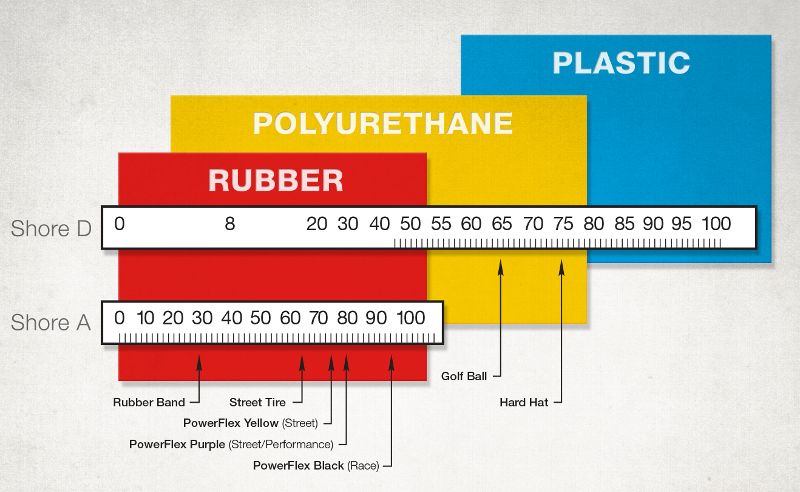

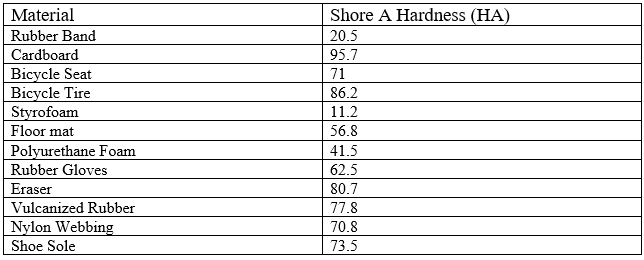

The shore a scale is used for measuring the hardness of softer more flexible materials.

Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials.

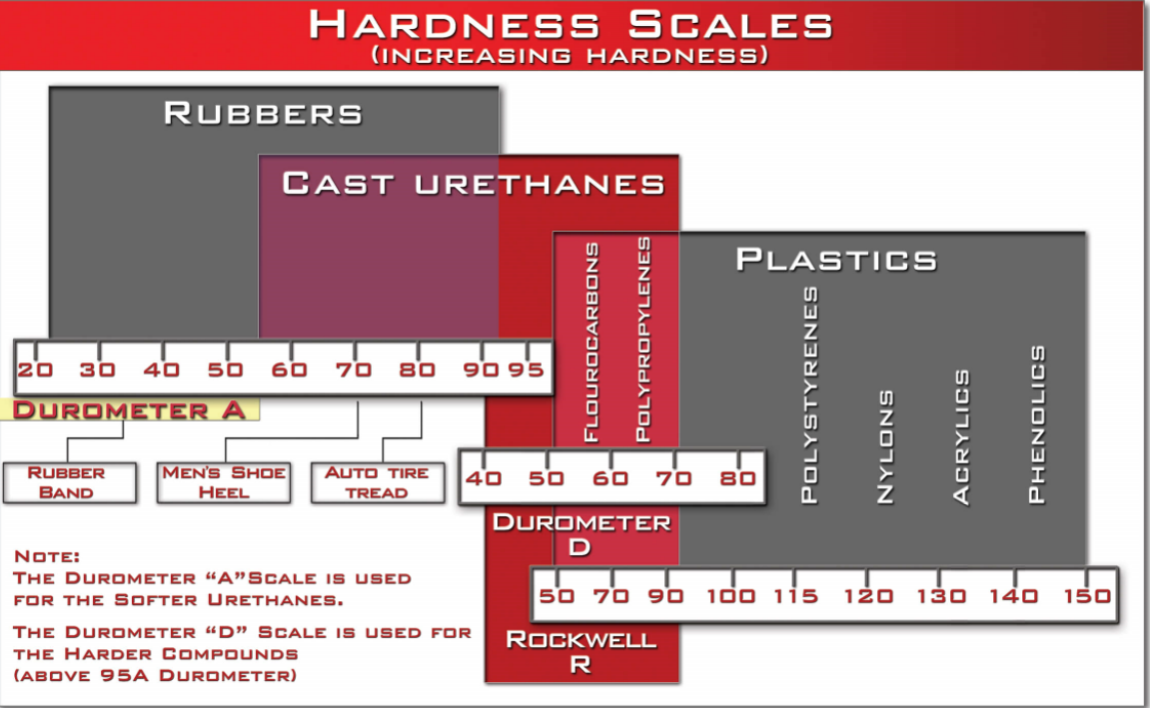

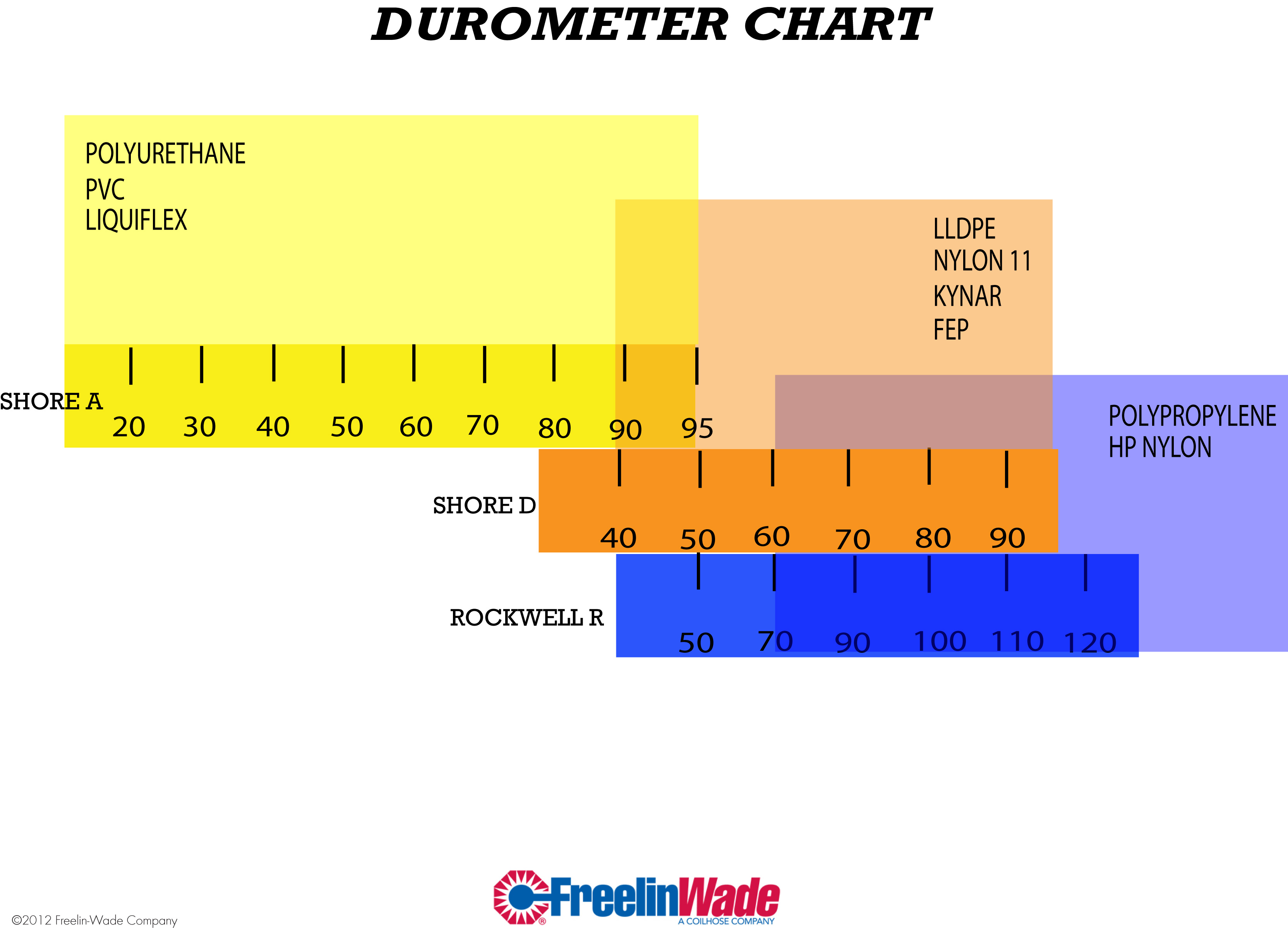

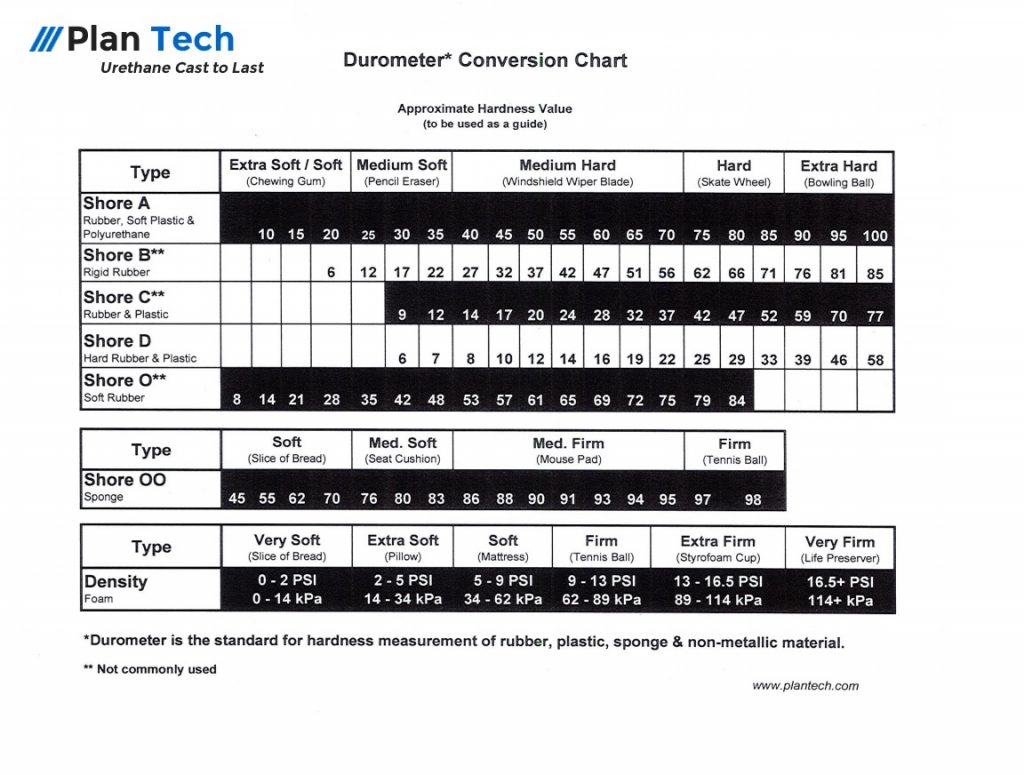

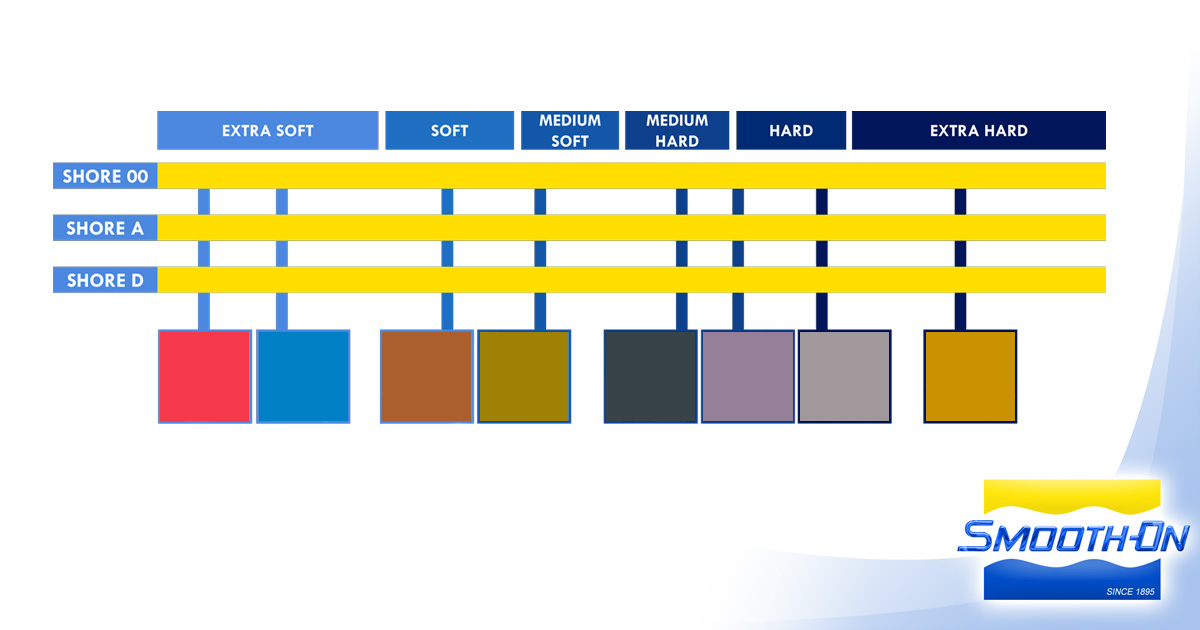

There are a various methods with which to measure durometer to encompass the wide range of hardness which these materials come in.

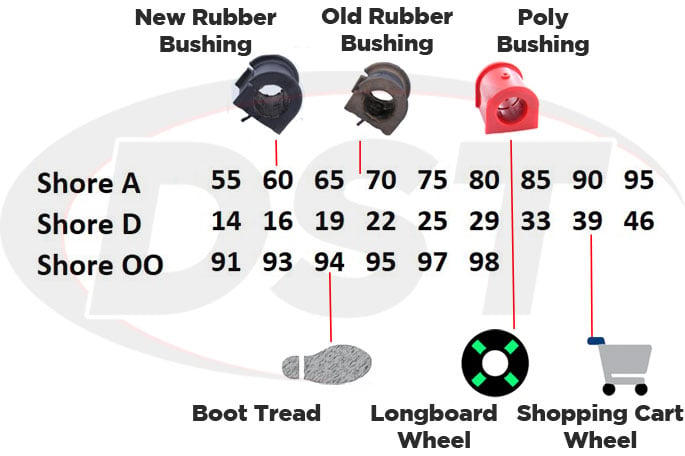

Shore a and shore 00 measure the hardness of softer materials while shore d measures the hardness of stiffer materials.

The shore a scale is used for measuring the hardness of softer more flexible materials.

Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials.

There are a various methods with which to measure durometer to encompass the wide range of hardness which these materials come in.

Shore a and shore 00 measure the hardness of softer materials while shore d measures the hardness of stiffer materials.

As the need for our products grew.

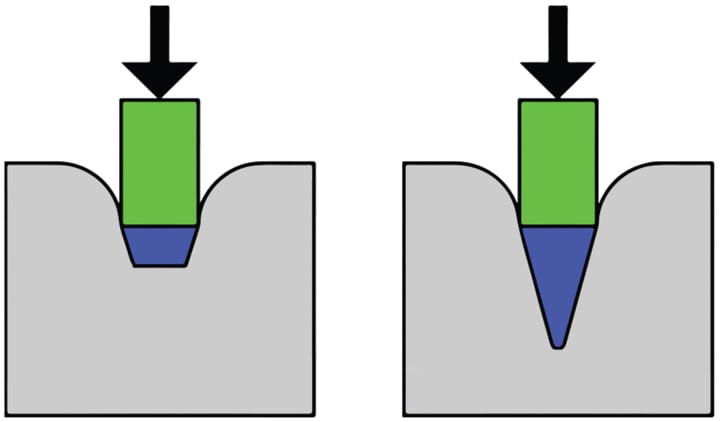

It is measured by the depth of indentation that is created on the material with a specified force.

The durometer scale measures hardness in terms of the elasticity of the material.

Technical data cast urethane hardness data back to technical data.

As the need for our products grew.

It is measured by the depth of indentation that is created on the material with a specified force.

The durometer scale measures hardness in terms of the elasticity of the material.

Technical data cast urethane hardness data back to technical data.

For example a material with a shore hardness of 95a is also a shore 45d.

Lower numbers indicate less resistance and softer materials.

The shore 00 hardness scale measures rubbers and gels that are very soft.

The shore a hardness scale measures the hardness of flexible mold rubbers that range in hardness from very soft and flexible to medium and somewhat flexible to hard with almost no flexibility at all.

For example a material with a shore hardness of 95a is also a shore 45d.

Lower numbers indicate less resistance and softer materials.

The shore 00 hardness scale measures rubbers and gels that are very soft.

The shore a hardness scale measures the hardness of flexible mold rubbers that range in hardness from very soft and flexible to medium and somewhat flexible to hard with almost no flexibility at all.

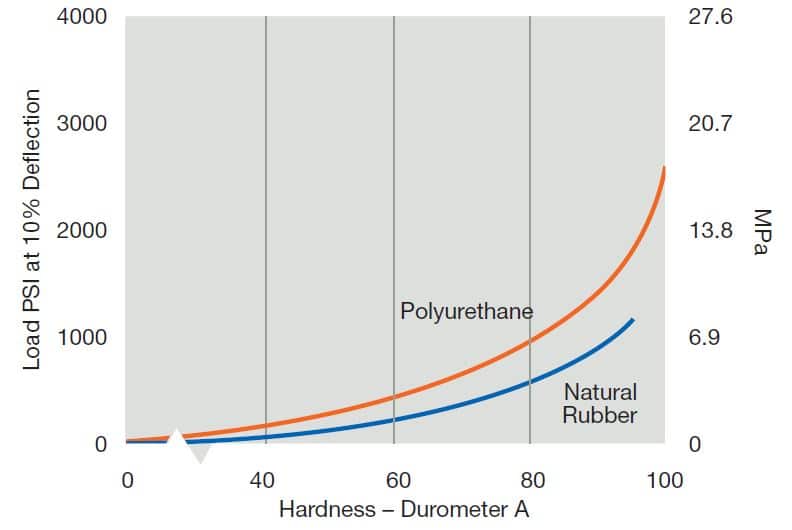

The hardness of any soft material such as rubber plastic polyurethane or non metallic material is measured in durometer which is similar to how steel is measured on the rockwell scale.

Durometer is a measure of indentation of a shaped pin into the elastomer surface at a given load.

The harder the material the higher the rebound.

The hardness of polyurethane is measured using the durometer scale.

The hardness of any soft material such as rubber plastic polyurethane or non metallic material is measured in durometer which is similar to how steel is measured on the rockwell scale.

Durometer is a measure of indentation of a shaped pin into the elastomer surface at a given load.

The harder the material the higher the rebound.

The hardness of polyurethane is measured using the durometer scale.

Was established over 49 years ago as a manufacturer dedicated to supplying quality custom molded polyurethane products to the local oil industry.

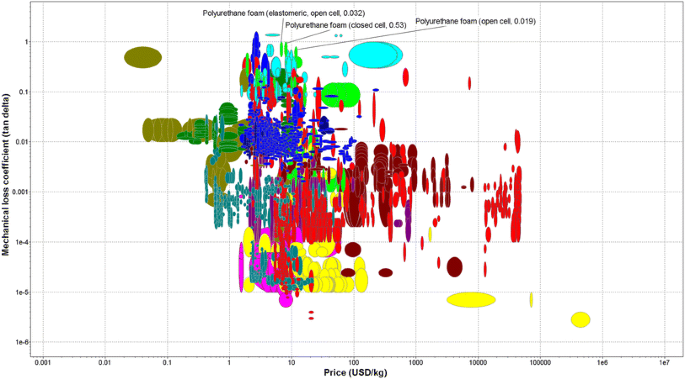

This is where we tend to see the most potential for polyurethane.

Cast urethane hardness data.

Durometer is the measure of hardness of an elastomer similar to rockewell hardness for steel.

Was established over 49 years ago as a manufacturer dedicated to supplying quality custom molded polyurethane products to the local oil industry.

This is where we tend to see the most potential for polyurethane.

Cast urethane hardness data.

Durometer is the measure of hardness of an elastomer similar to rockewell hardness for steel.

Shore a d and 00 are the most commonly used scales.

However polyurethanes commonly use only three scales including a d or 00.

There are several different durometer scales used to properly measure a materials hardness.

Durometer is one of the most critical properties to consider when selecting the right.

Shore a d and 00 are the most commonly used scales.

However polyurethanes commonly use only three scales including a d or 00.

There are several different durometer scales used to properly measure a materials hardness.

Durometer is one of the most critical properties to consider when selecting the right.

Hardness scales increasing hardness.

However other scales such as b c and o are occasionally used.

The shore durometer is a device for measuring the hardness of a material typically of polymers elastomers and rubbers.

Shore hardness is nothing but a measure of the hardness of a given material or how resistant it will be to permanent indentation.

Hardness scales increasing hardness.

However other scales such as b c and o are occasionally used.

The shore durometer is a device for measuring the hardness of a material typically of polymers elastomers and rubbers.

Shore hardness is nothing but a measure of the hardness of a given material or how resistant it will be to permanent indentation.

A diamond tipped hammer in a graduated glass tube is allowed to fall from a known height on the specimen to be tested and the hardness number depends on the height to which the hammer rebounds.

A diamond tipped hammer in a graduated glass tube is allowed to fall from a known height on the specimen to be tested and the hardness number depends on the height to which the hammer rebounds.