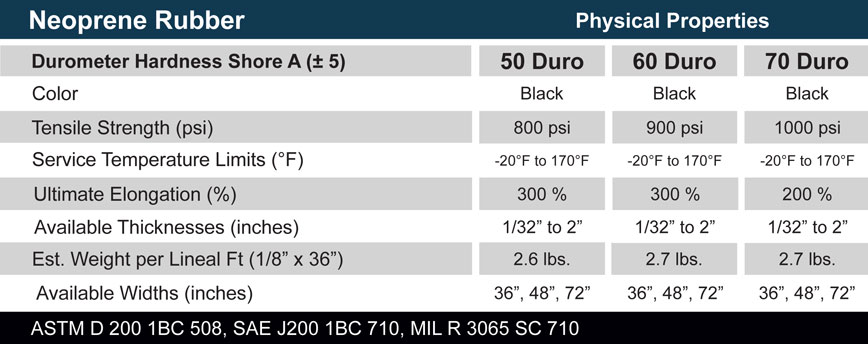

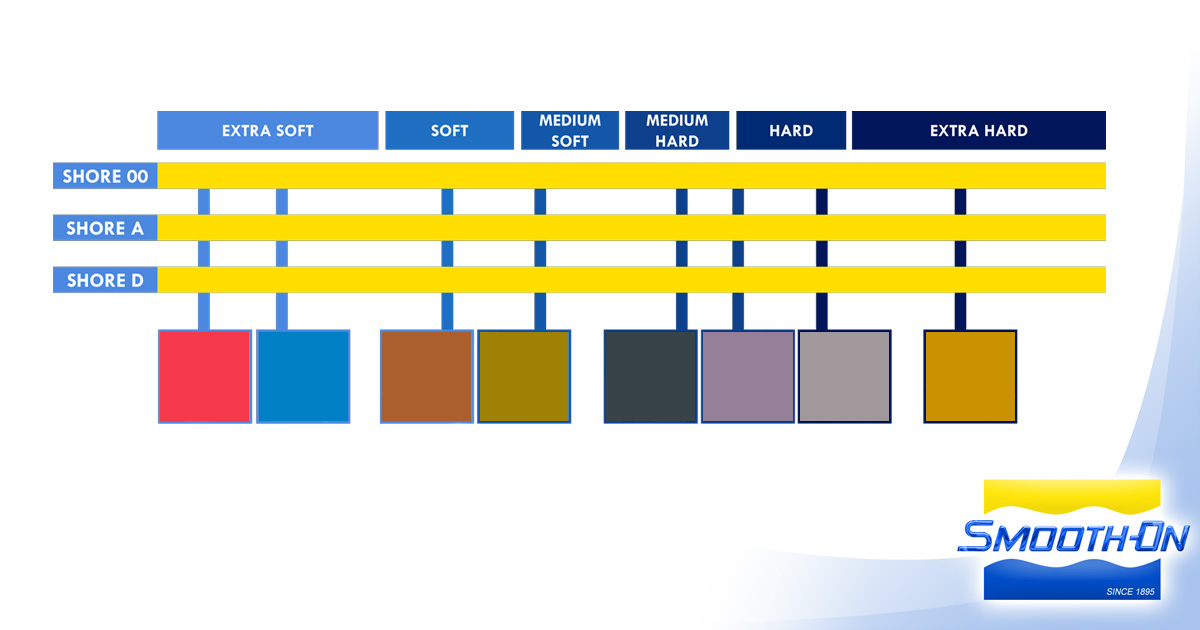

Inspiration Shore A Rubber Density, Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials.

Shore a rubber density.

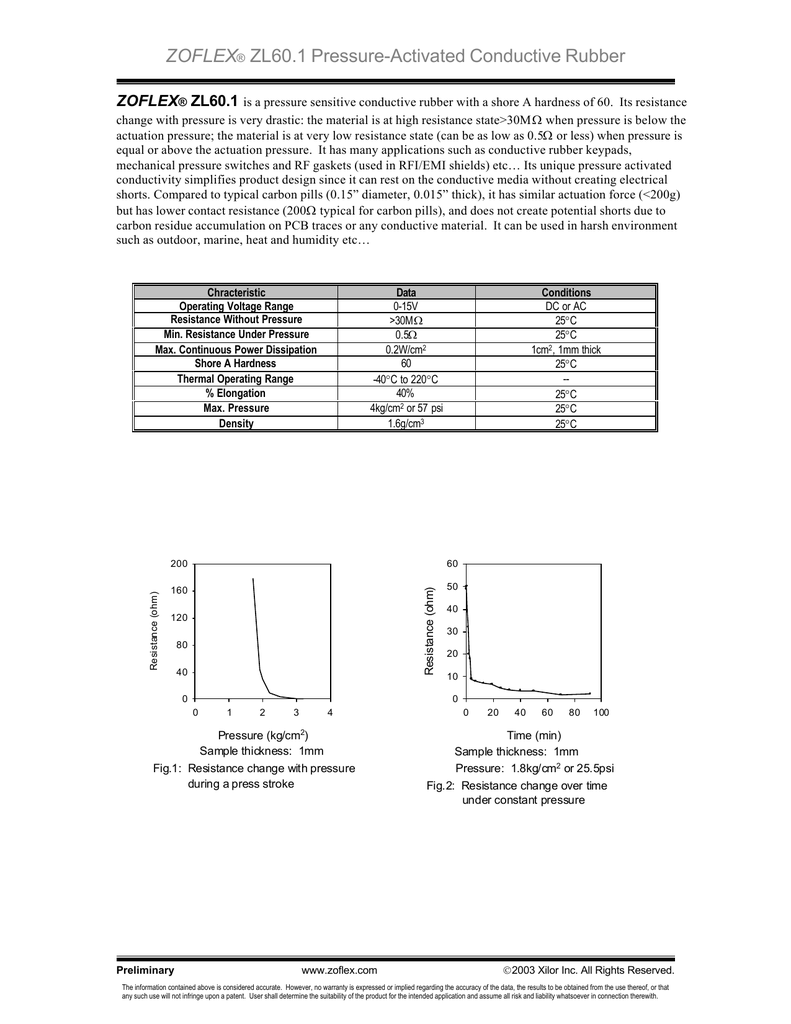

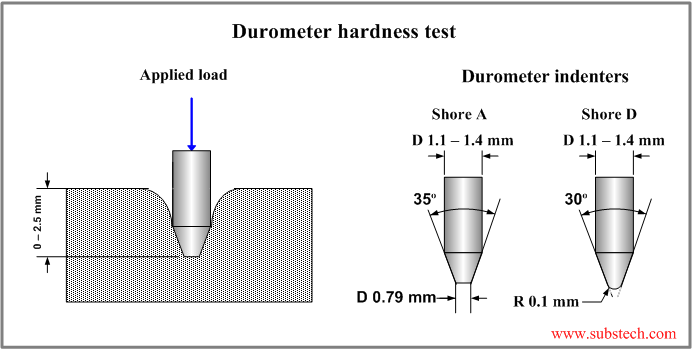

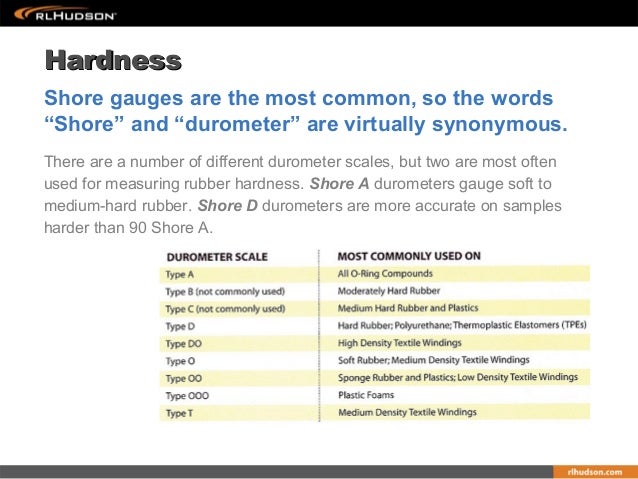

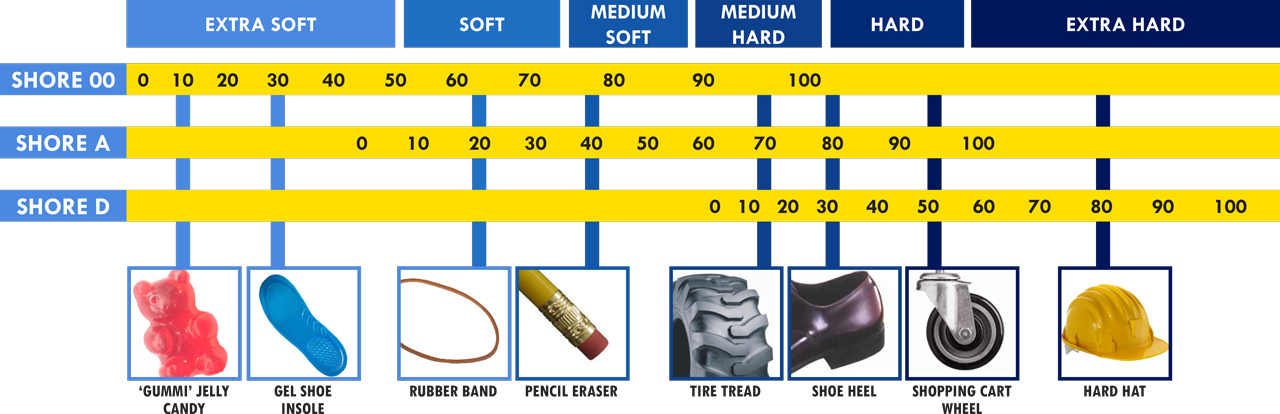

The shore durometer is a device for measuring the hardness of a material typically of polymers elastomers and rubbers.

In accordance with jis k 6249 test pieces.

The m class comprises elastomers having a saturated chain of the polyethylene type the m deriving from the more correct term polymethylene.

Shore a rubber soft plastic polyurethane 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 shore b rigid rubber 6 12 17 22 27 32 37 42 47 51 56 62 66 71 76 81 85 shore c rubber plastic 9 12 14 17 20 24 28 32 37 42 47 52 59 70 77 shore d hard rubber plastic 6 7 8 10 12 14 16 19 22 25 29 33 39 46 58 shore o.

The shore durometer is a device for measuring the hardness of a material typically of polymers elastomers and rubbers.

In accordance with jis k 6249 test pieces.

The m class comprises elastomers having a saturated chain of the polyethylene type the m deriving from the more correct term polymethylene.

Shore a rubber soft plastic polyurethane 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 shore b rigid rubber 6 12 17 22 27 32 37 42 47 51 56 62 66 71 76 81 85 shore c rubber plastic 9 12 14 17 20 24 28 32 37 42 47 52 59 70 77 shore d hard rubber plastic 6 7 8 10 12 14 16 19 22 25 29 33 39 46 58 shore o.

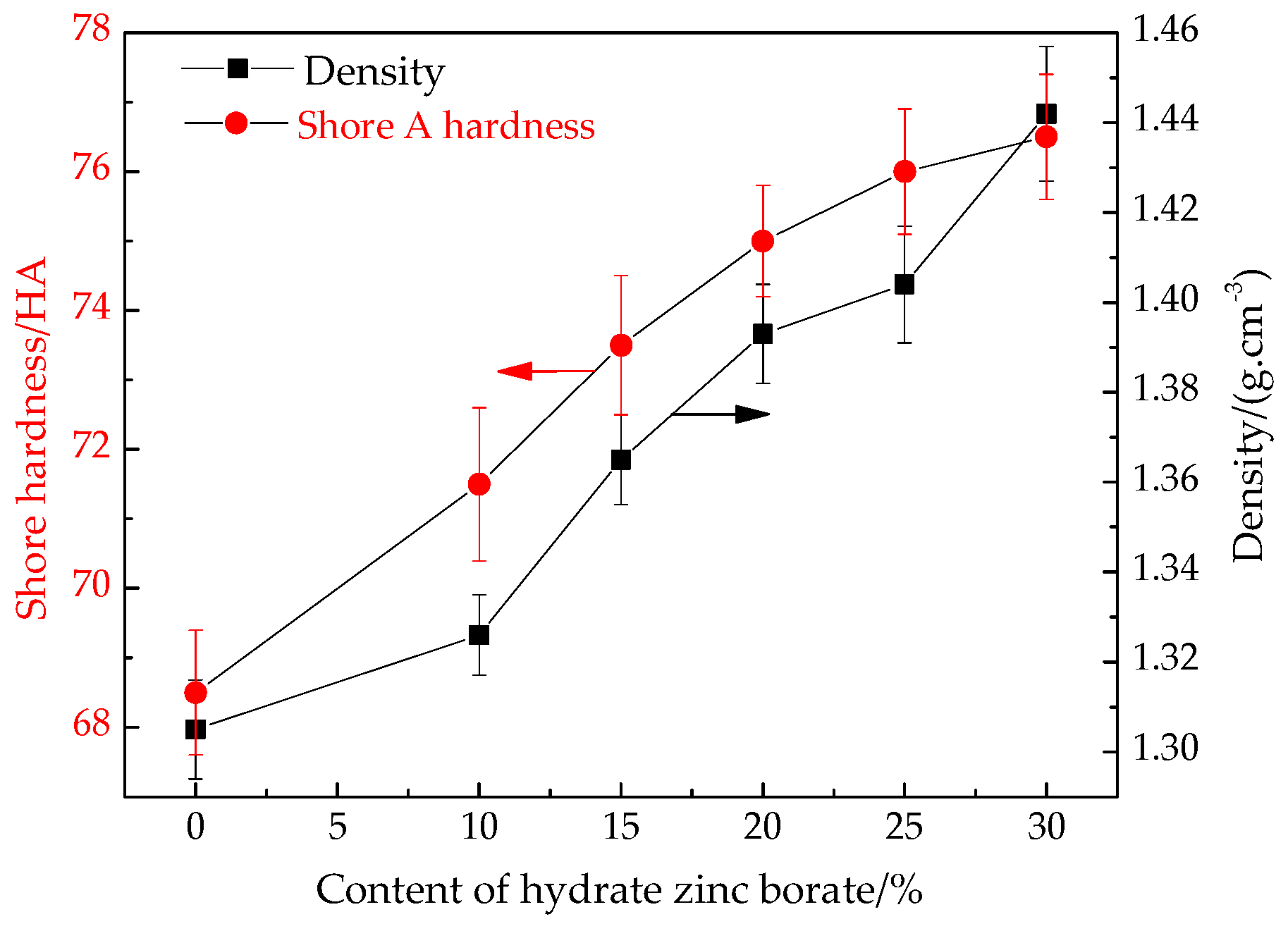

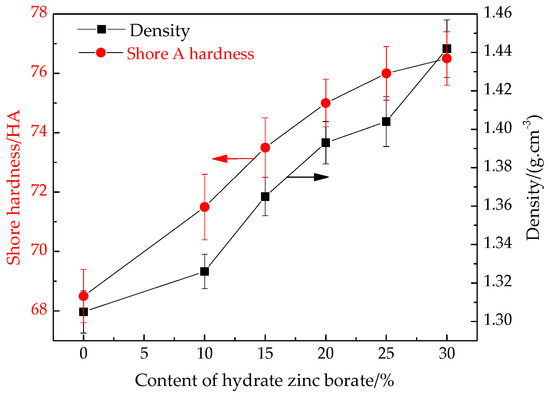

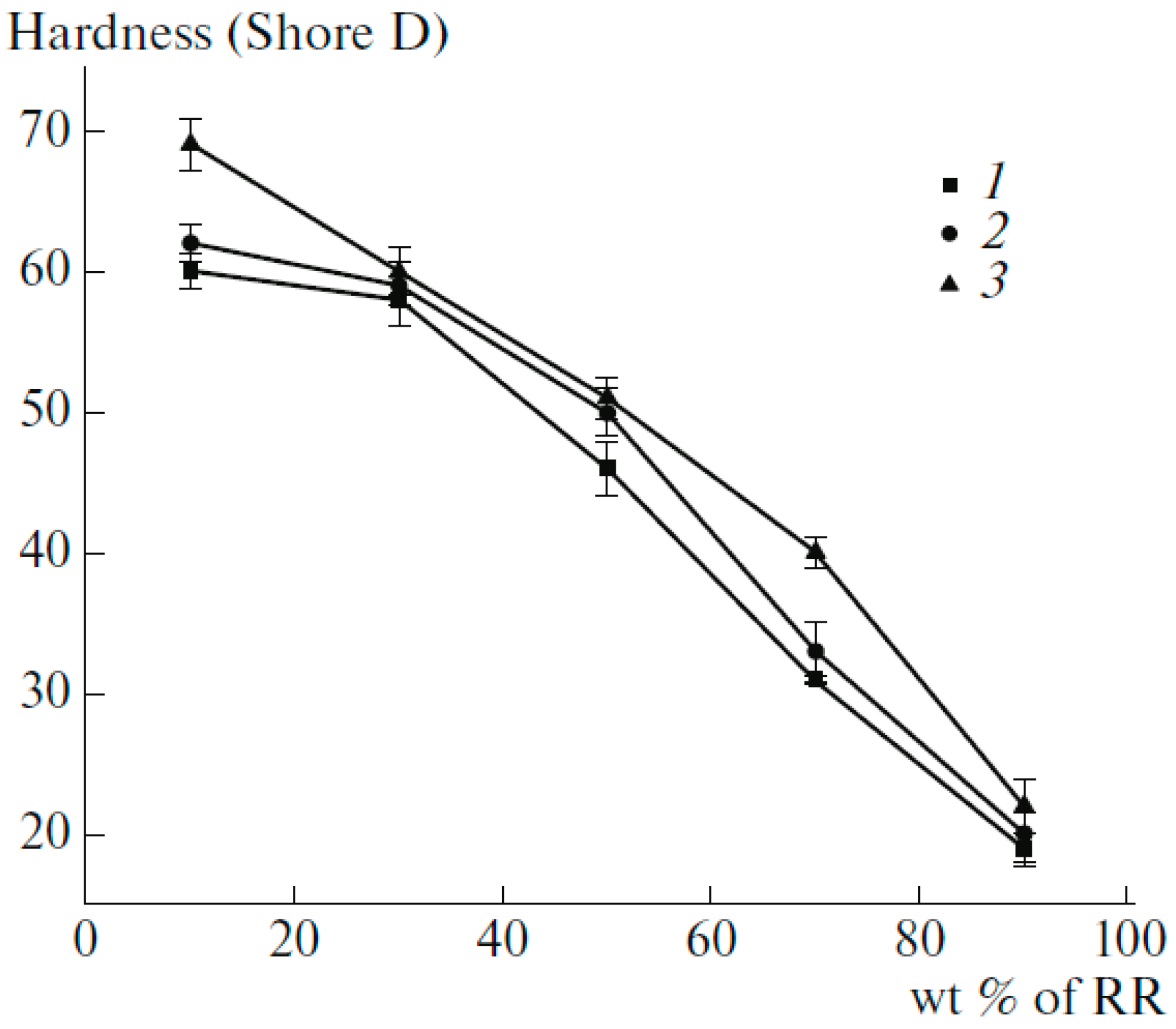

Durometer correlates with a materials density.

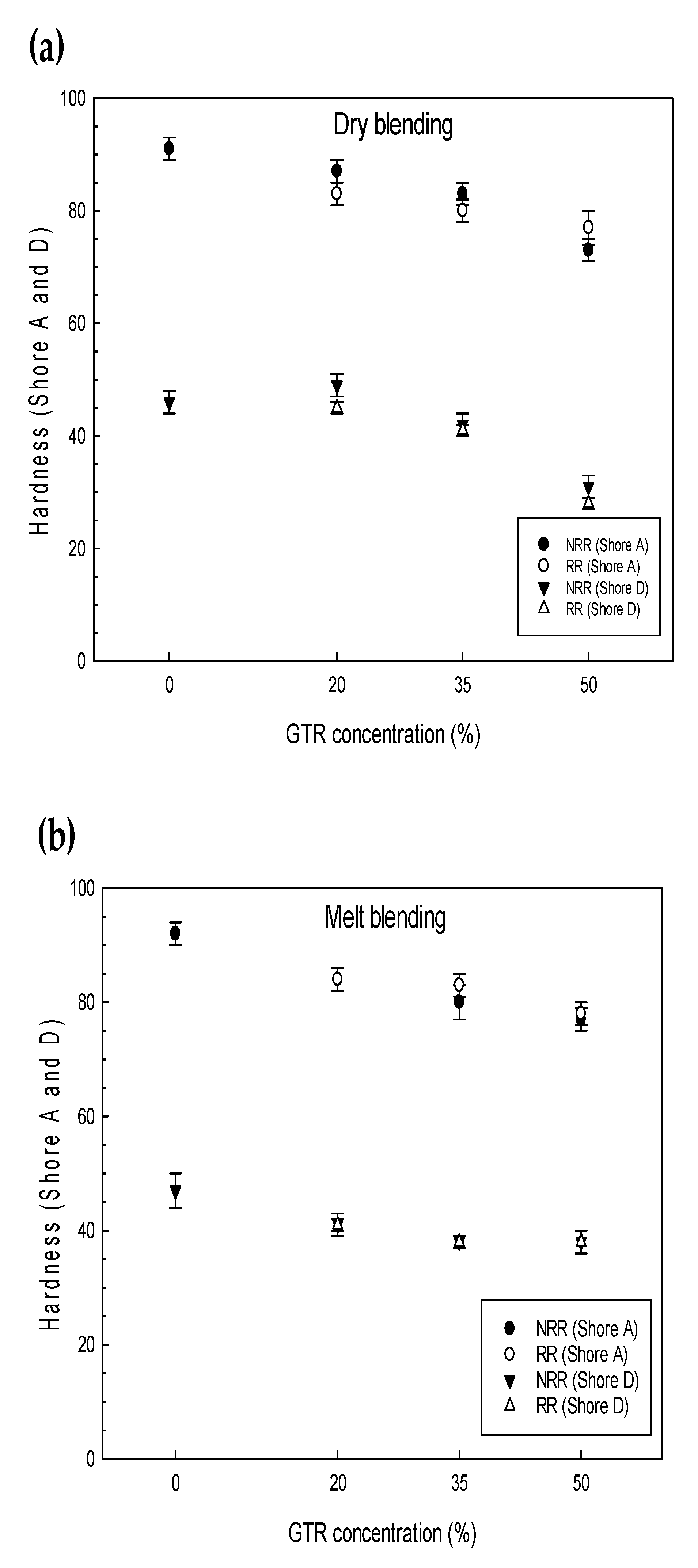

The rubber durometer chart below gives you an idea of the rubber hardness that you want for your application.

Other items measured on the shore a scale include rubber bands 30 shore a and tire treads 60 shore a.

Epdm is made from ethylene propylene and a diene comonomer that enables.

Durometer correlates with a materials density.

The rubber durometer chart below gives you an idea of the rubber hardness that you want for your application.

Other items measured on the shore a scale include rubber bands 30 shore a and tire treads 60 shore a.

Epdm is made from ethylene propylene and a diene comonomer that enables.

Epdm sheet rubber is a versatile blended sheet composed of ethylene propylene diene monomer and styrene butadiene rubber.

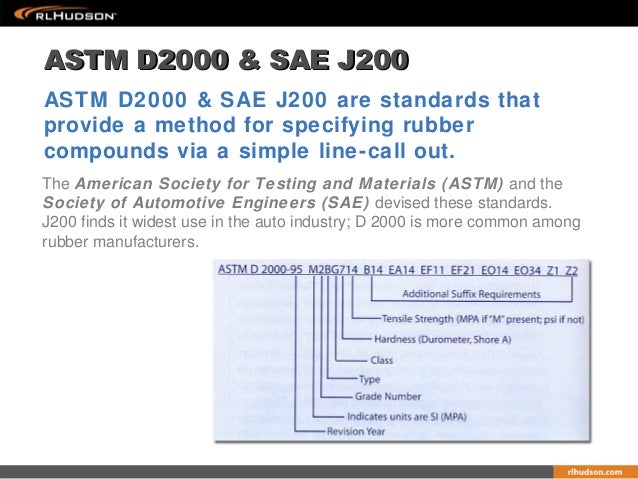

Epdm is an m class rubber under astm standard d 1418.

Thus if you need a rubber or o ring durometer that feels like a running shoe sole review our rubber hardness chart below then pick shore 70a.

2 instruments in 1.

Epdm sheet rubber is a versatile blended sheet composed of ethylene propylene diene monomer and styrene butadiene rubber.

Epdm is an m class rubber under astm standard d 1418.

Thus if you need a rubber or o ring durometer that feels like a running shoe sole review our rubber hardness chart below then pick shore 70a.

2 instruments in 1.

The epdm properties that are listed below are for our most popular epdm 70 durometer 70a rubber material.

Epdm rubber ethylene propylene diene monomer rubber is a type of synthetic rubber that is used in many applications.

Generally most rubber materials fall under the rubber durometer scale of shore a.

With the montech hd 3000 hardness and density testing of cured rubber samples is made simple fast and reliable.

The epdm properties that are listed below are for our most popular epdm 70 durometer 70a rubber material.

Epdm rubber ethylene propylene diene monomer rubber is a type of synthetic rubber that is used in many applications.

Generally most rubber materials fall under the rubber durometer scale of shore a.

With the montech hd 3000 hardness and density testing of cured rubber samples is made simple fast and reliable.

Arbitrary test sequences are easily pre programmed samples are sequentially processed and test data is automatically collected without the need for operator involvement.

It achieves an ideal balance to create an all purpose weather resistant rubber.

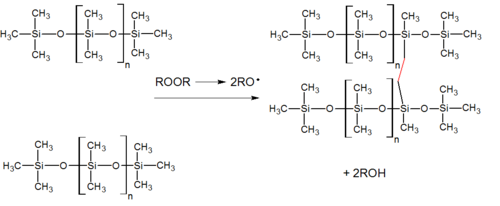

1650c x 10 min press cure 2000c x 4 h post cure 1 standard addition quantity is the quantity of curing agent added to 100 parts compound.

2 linear shrinkage values differ according to the curing agent used.

Arbitrary test sequences are easily pre programmed samples are sequentially processed and test data is automatically collected without the need for operator involvement.

It achieves an ideal balance to create an all purpose weather resistant rubber.

1650c x 10 min press cure 2000c x 4 h post cure 1 standard addition quantity is the quantity of curing agent added to 100 parts compound.

2 linear shrinkage values differ according to the curing agent used.

Density of aqueous solutions of organic acids changes in density of aqueous solutions with changes in concentration at 200c.

Lower numbers indicate less resistance and softer materials.

If you need epdm properties that are different than the ones shown in the chart below we can reformulate the compound of the epdm material so that the epdm rubber specifications suit your needs.

Density of aqueous solutions of organic acids changes in density of aqueous solutions with changes in concentration at 200c.

Lower numbers indicate less resistance and softer materials.

If you need epdm properties that are different than the ones shown in the chart below we can reformulate the compound of the epdm material so that the epdm rubber specifications suit your needs.

.png)