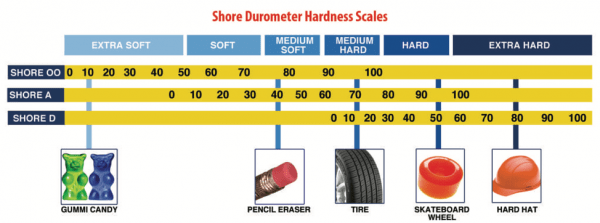

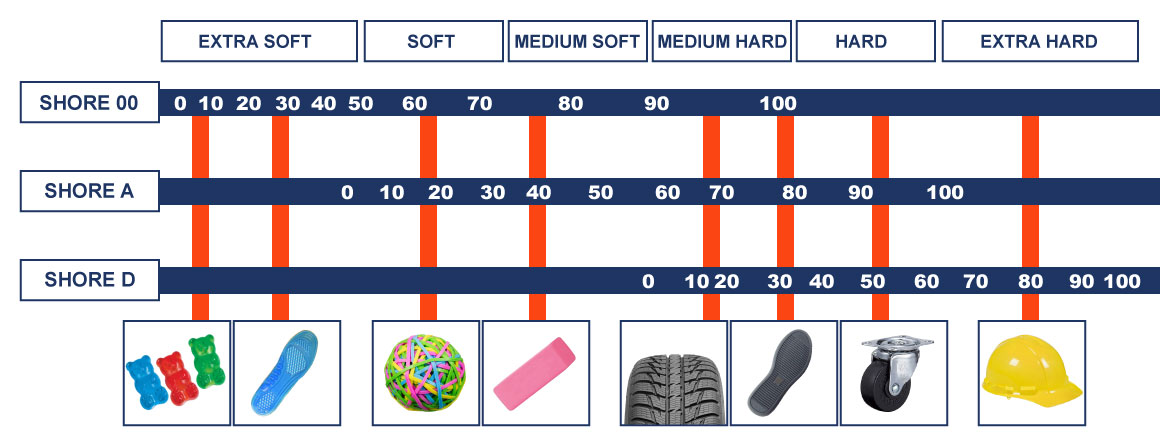

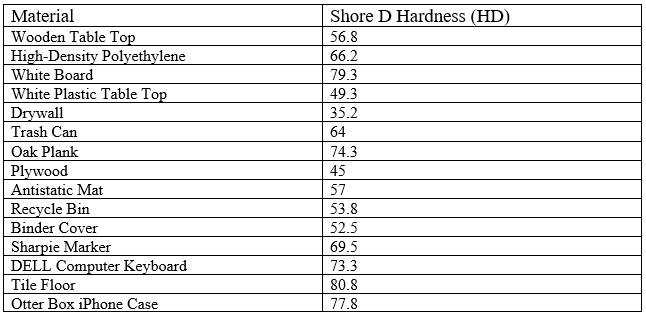

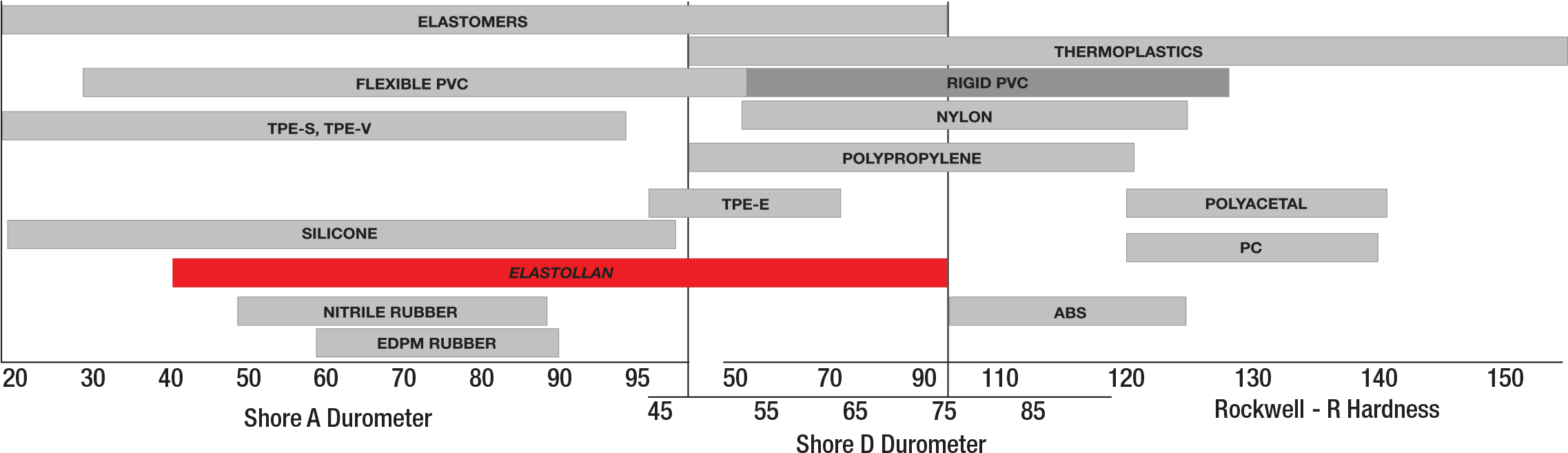

Top Shore D Hardness Values, The shore a hardness measurement is called durometer.

Shore d hardness values.

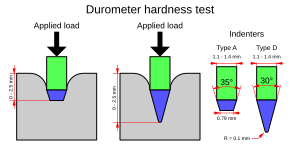

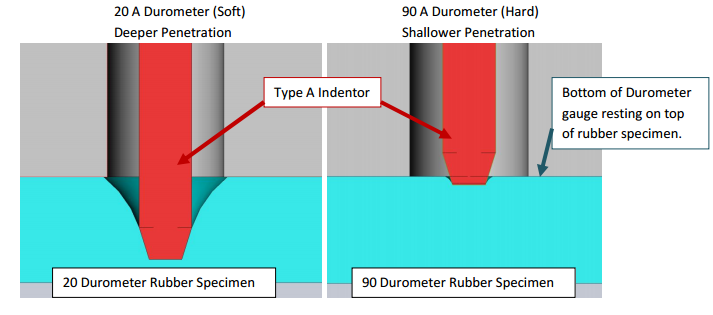

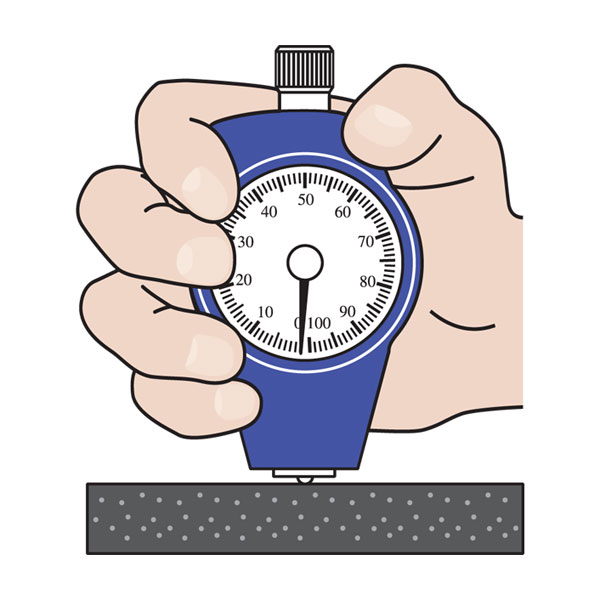

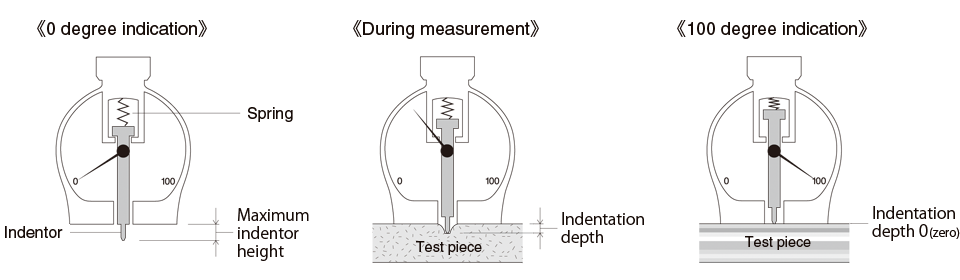

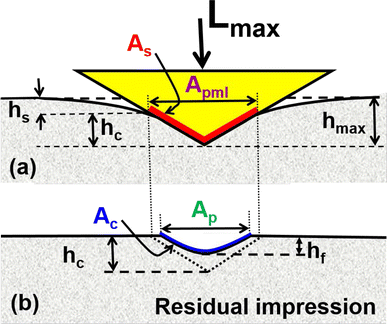

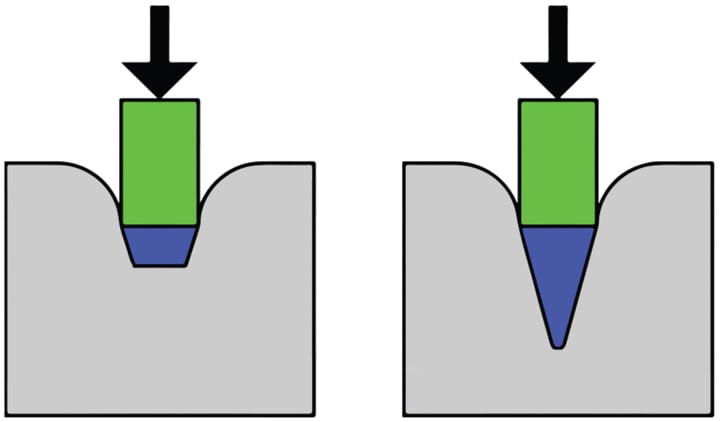

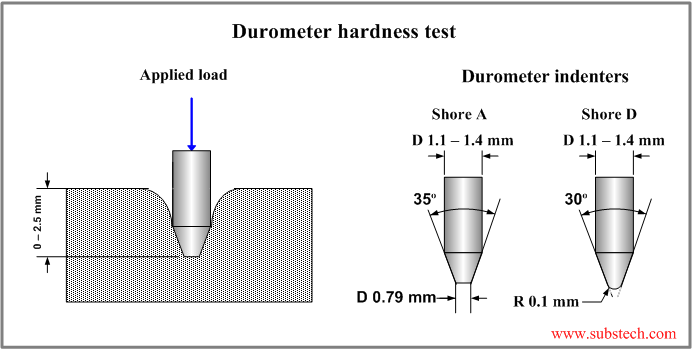

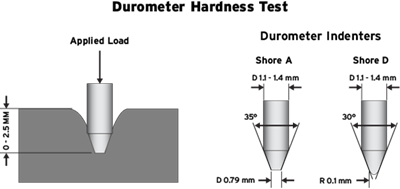

The final value of the hardness depends on the depth of the indenter after it has been applied for 15 seconds on the material.

Shore hardness is often used as an indication of flexibility or stiffness which is called flexural modulus.

Five measurements need to be taken.

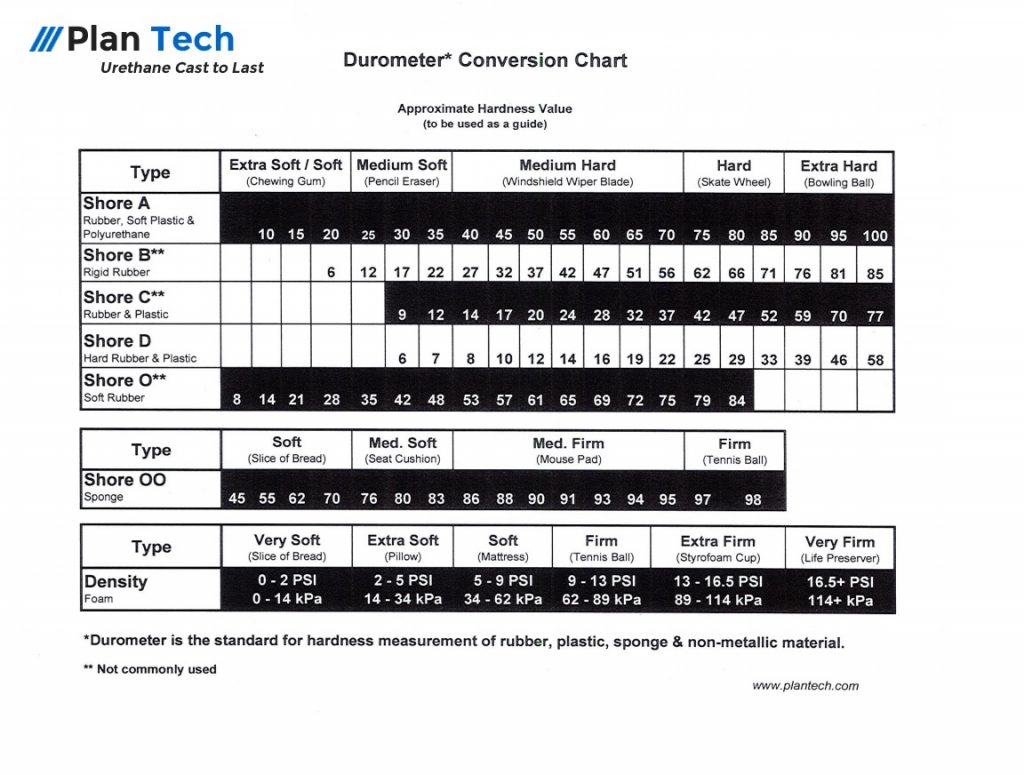

If you prefer to use microsoft excel to convert durometer readings to their youngs modulus values use the following formula for the result cell.

The final value of the hardness depends on the depth of the indenter after it has been applied for 15 seconds on the material.

Shore hardness is often used as an indication of flexibility or stiffness which is called flexural modulus.

Five measurements need to be taken.

If you prefer to use microsoft excel to convert durometer readings to their youngs modulus values use the following formula for the result cell.

Expa15000235 06403 where a1 is the cell with the shore d durometer value.

Rockwell vs shore hardness.

Shore hardness measures are dimensionless.

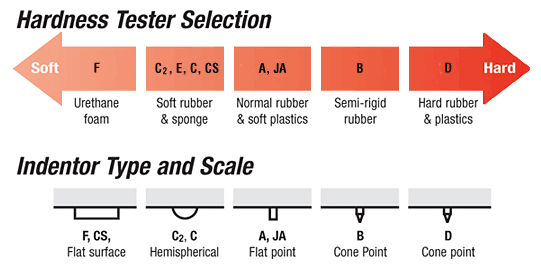

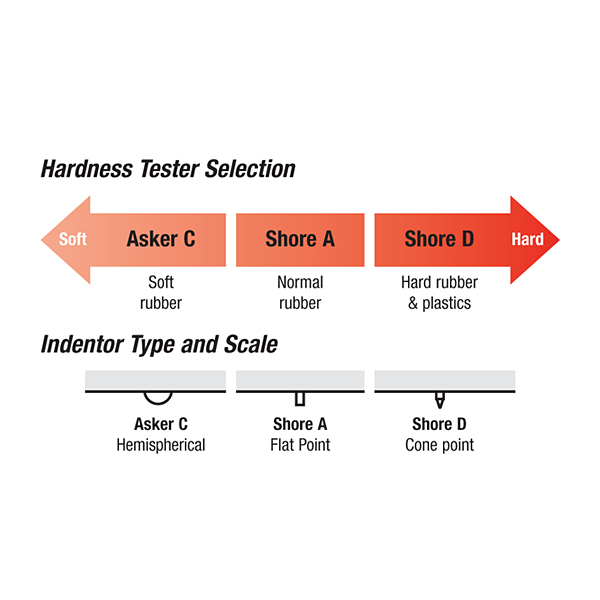

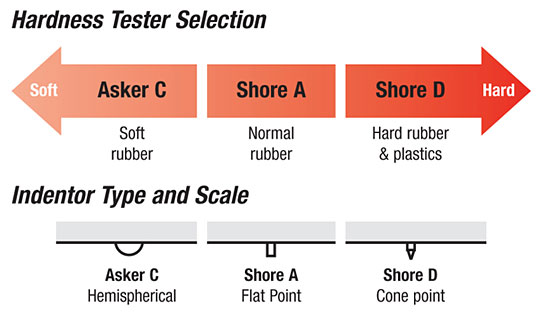

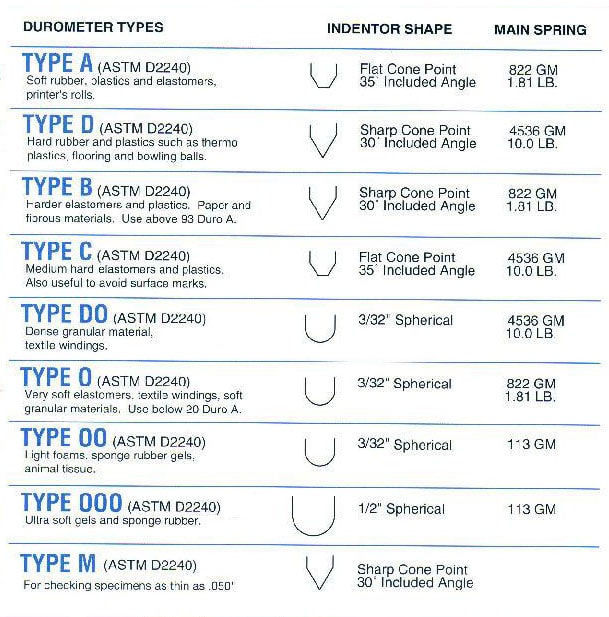

Force is 1 kg 01 kg for shore a and 5 kg 05 kg for shore d.

Expa15000235 06403 where a1 is the cell with the shore d durometer value.

Rockwell vs shore hardness.

Shore hardness measures are dimensionless.

Force is 1 kg 01 kg for shore a and 5 kg 05 kg for shore d.

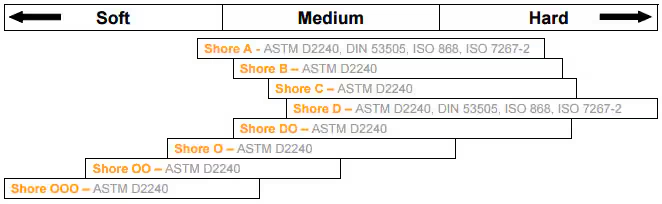

Test methods used to measure shore d hardness are astm d2240 and iso 868.

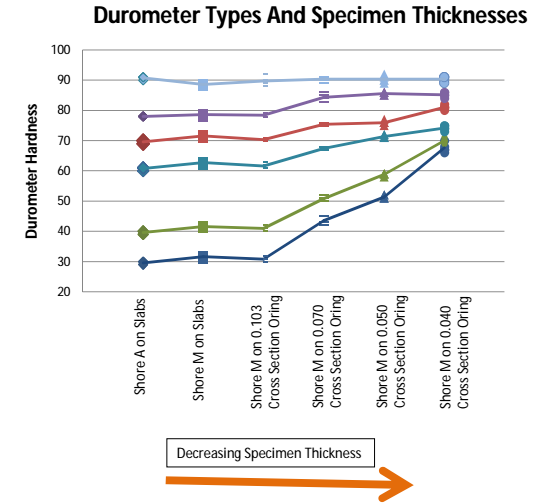

Tests are carried out on cured rubber according to astm d2240 and on a complete o ring according to astm d1414.

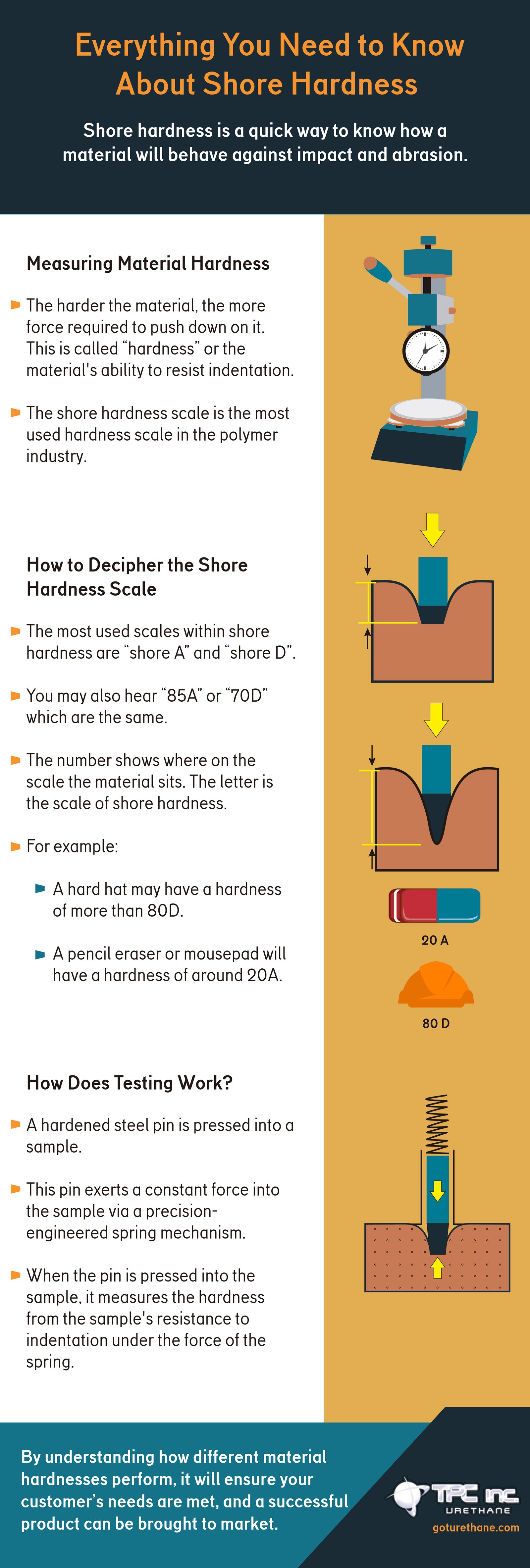

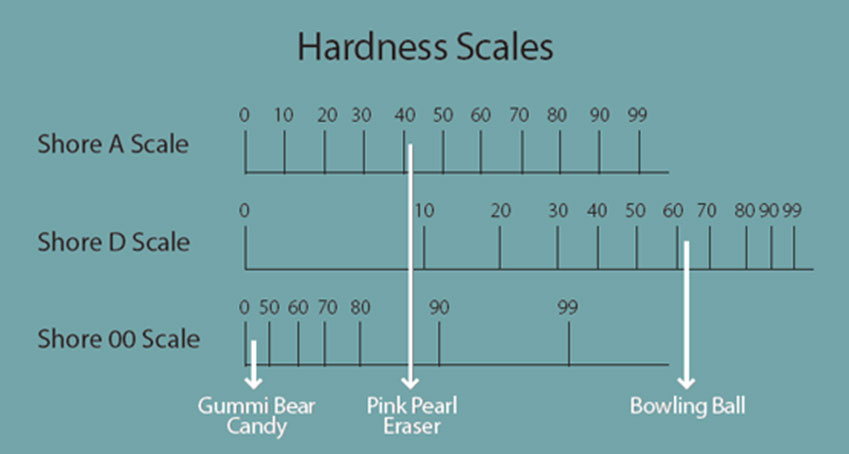

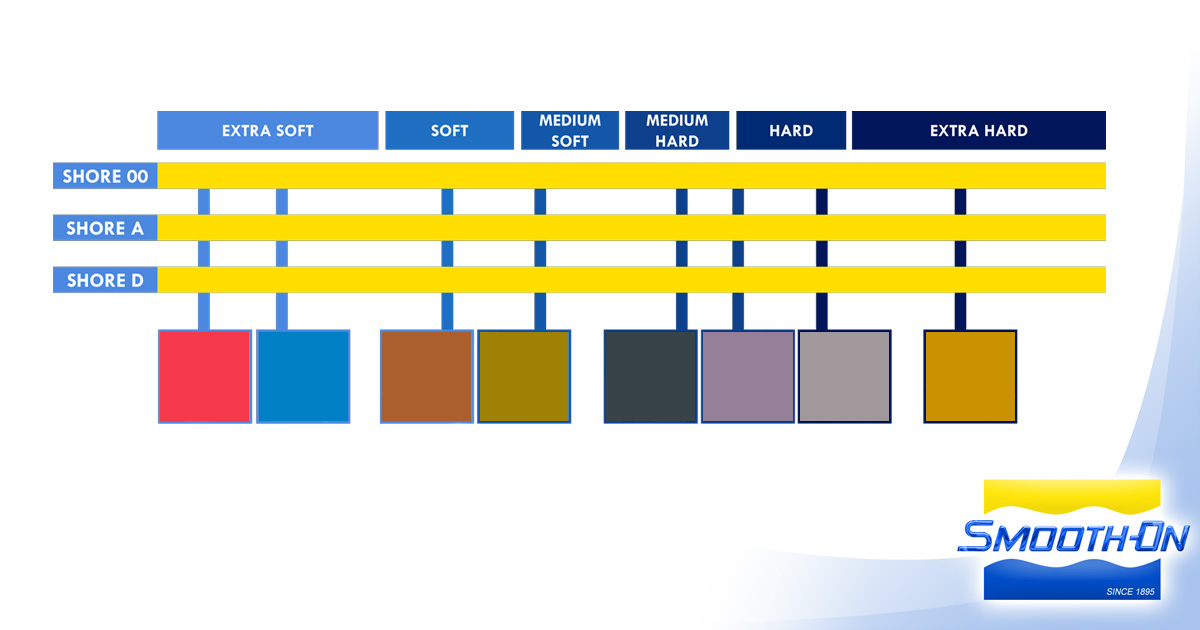

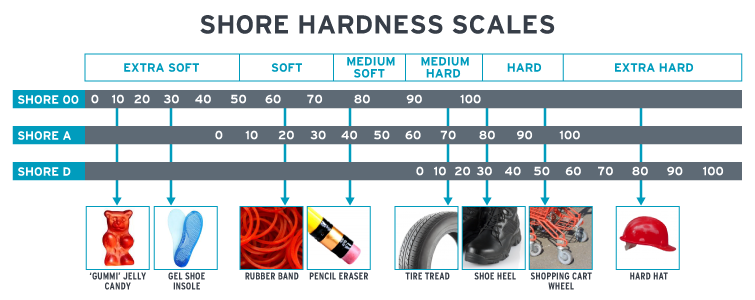

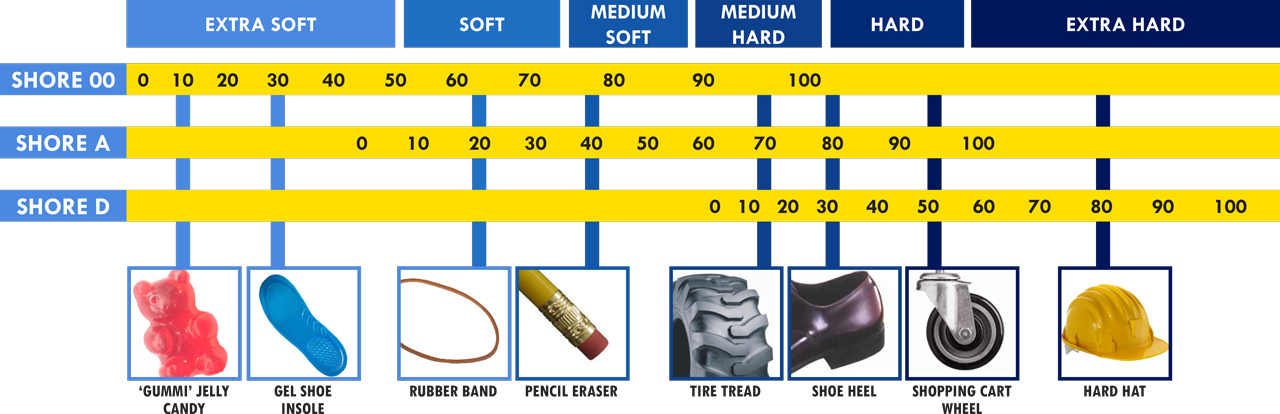

Each scale ranks hardness values between 0 and 100 with higher values indicating higher hardness.

A standardised test used industry wide the shore d hardness technique measures the depth of penetration of an indenter generally using astm d2240 and iso 868 test methods.

Test methods used to measure shore d hardness are astm d2240 and iso 868.

Tests are carried out on cured rubber according to astm d2240 and on a complete o ring according to astm d1414.

Each scale ranks hardness values between 0 and 100 with higher values indicating higher hardness.

A standardised test used industry wide the shore d hardness technique measures the depth of penetration of an indenter generally using astm d2240 and iso 868 test methods.

The shore d scale measures hard rubbers and semi rigid and rigid plastics.

The hardness value is determined by the penetration of the durometer indenter foot into the sample.

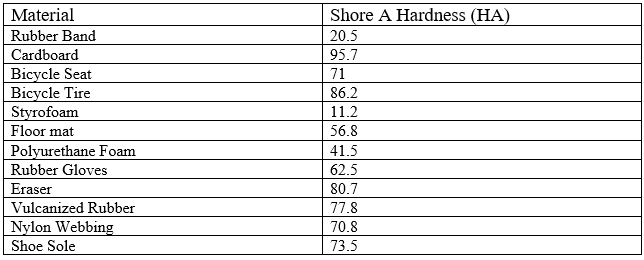

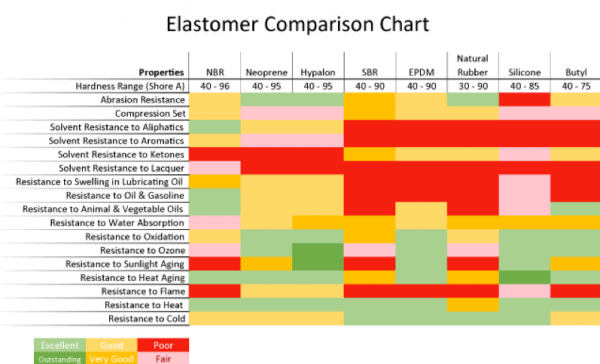

The shore a hardness scale measures the hardness of flexible mold rubbers that range in hardness from very soft and flexible to medium and somewhat flexible to hard with almost no flexibility at all.

Other rockwell hardness scales are used for metals with rockwell a b and c being the three most common scales.

The shore d scale measures hard rubbers and semi rigid and rigid plastics.

The hardness value is determined by the penetration of the durometer indenter foot into the sample.

The shore a hardness scale measures the hardness of flexible mold rubbers that range in hardness from very soft and flexible to medium and somewhat flexible to hard with almost no flexibility at all.

Other rockwell hardness scales are used for metals with rockwell a b and c being the three most common scales.

Shore d hardness scale is reserved for measuring the hardness of hard rubbers semi rigid plastics and hard plastics.

With readings taken between 0 and 100 shore hardness measures are dimensionless.

The shore durometer is an instrument used for measuring the materials hardness generally rubbers elastomers and polymers.

While not needed for plaster casting shore hardness proves helpful when you have to choose your materials such as which silicone rubber should be used for making a mold or cast.

Shore d hardness scale is reserved for measuring the hardness of hard rubbers semi rigid plastics and hard plastics.

With readings taken between 0 and 100 shore hardness measures are dimensionless.

The shore durometer is an instrument used for measuring the materials hardness generally rubbers elastomers and polymers.

While not needed for plaster casting shore hardness proves helpful when you have to choose your materials such as which silicone rubber should be used for making a mold or cast.

The rockwell hardness scales use different size steel balls and different loads.

Shore d hardness is a standardized test consisting in measuring the depth of penetration of a specific indenter.

Shore hardness and how it relates to other properties.

For shore a values omit the 50.

The rockwell hardness scales use different size steel balls and different loads.

Shore d hardness is a standardized test consisting in measuring the depth of penetration of a specific indenter.

Shore hardness and how it relates to other properties.

For shore a values omit the 50.

Semi rigid plastics can also be measured on the high end of the shore a scale.

Calibration of the durometer is one per week with elastomer blocks of different hardness.

The shore a scale is suitable for materials ranging from soft and flexible ones to semi rigid relatively inflexible plastics.

The shore d hardness scale measures the hardness of hard rubbers semi rigid plastics and hard plastics.

Semi rigid plastics can also be measured on the high end of the shore a scale.

Calibration of the durometer is one per week with elastomer blocks of different hardness.

The shore a scale is suitable for materials ranging from soft and flexible ones to semi rigid relatively inflexible plastics.

The shore d hardness scale measures the hardness of hard rubbers semi rigid plastics and hard plastics.

.png)