Top Shore Hardness Of O Ring, Why is shore a hardness important.

Shore hardness of o ring.

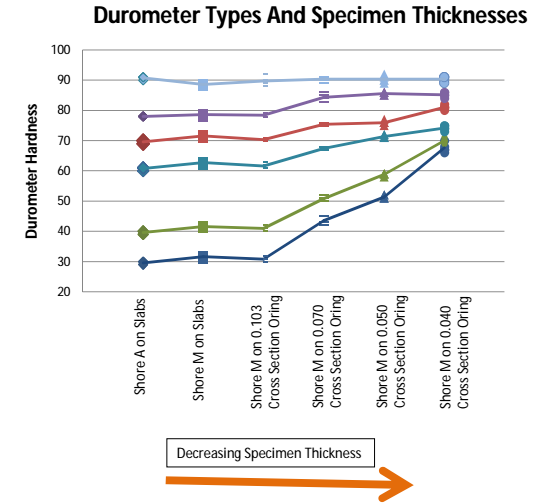

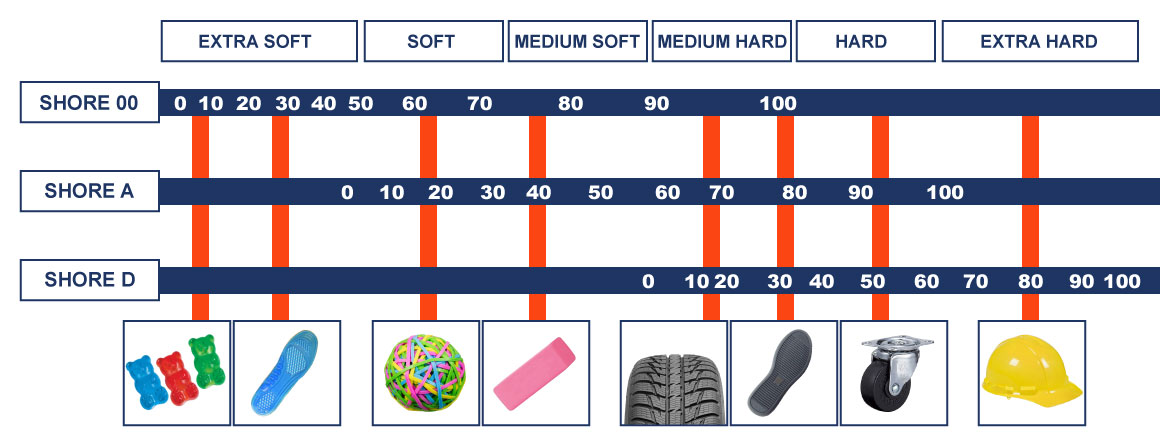

The hardness of rubber o rings are measure by the shore a durometer.

Throughout the seal industry the shore a type durometer scale manufactured by a variety of manufacturers is the standard instrument used to measure the hardness of most rubber compounds.

Tests are carried out on cured rubber according to astm d2240 and on a complete o ring according to astm d1414.

A guide to shore hardness and why its important when selecting o rings and seals.

The hardness of rubber o rings are measure by the shore a durometer.

Throughout the seal industry the shore a type durometer scale manufactured by a variety of manufacturers is the standard instrument used to measure the hardness of most rubber compounds.

Tests are carried out on cured rubber according to astm d2240 and on a complete o ring according to astm d1414.

A guide to shore hardness and why its important when selecting o rings and seals.

70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o rings applications.

The higher the durometer the harder the compound.

In general 70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o ring applications.

Compound n0674 70 has a shore a hardness of 70 while nm304 75 has a shore a hardness of 75.

70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o rings applications.

The higher the durometer the harder the compound.

In general 70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o ring applications.

Compound n0674 70 has a shore a hardness of 70 while nm304 75 has a shore a hardness of 75.

Five measurements need to be taken.

Calibration of the durometer is one per week with elastomer blocks of different hardness.

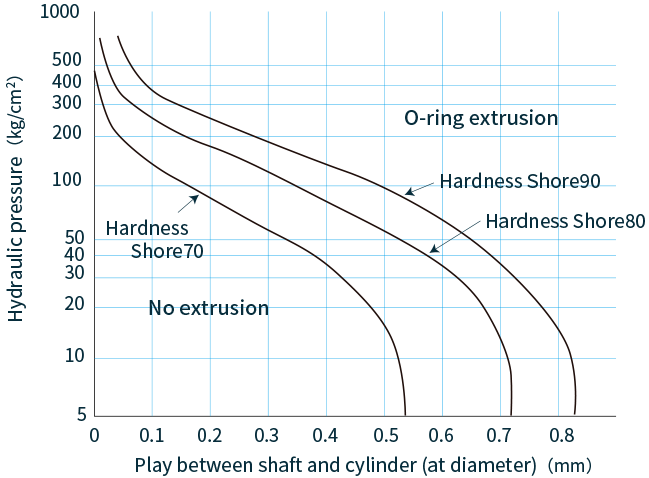

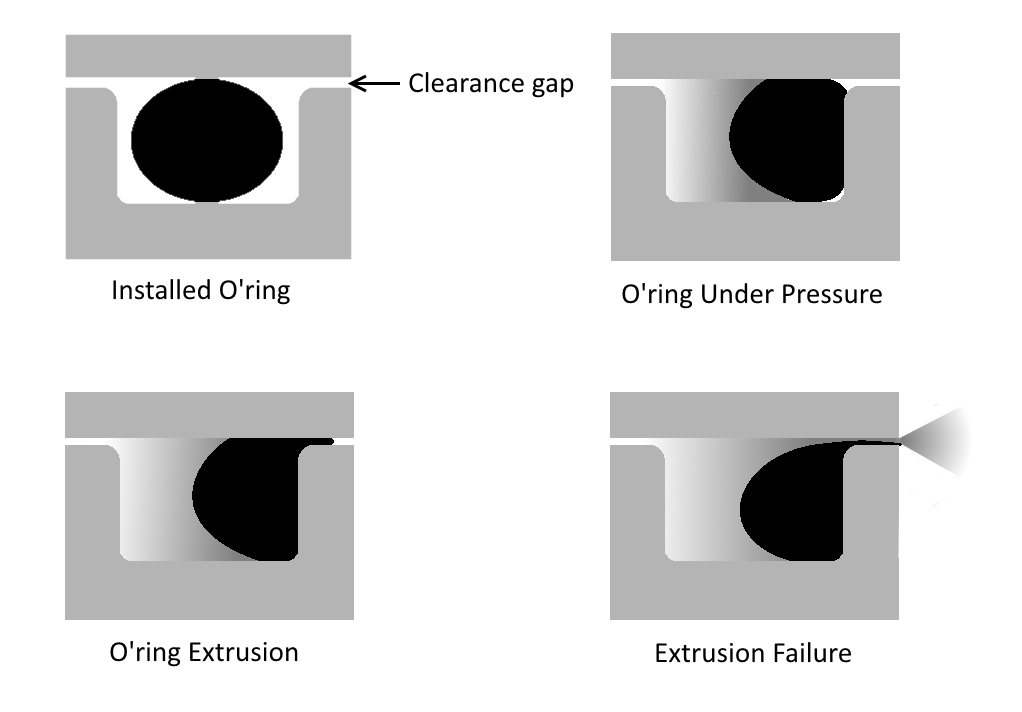

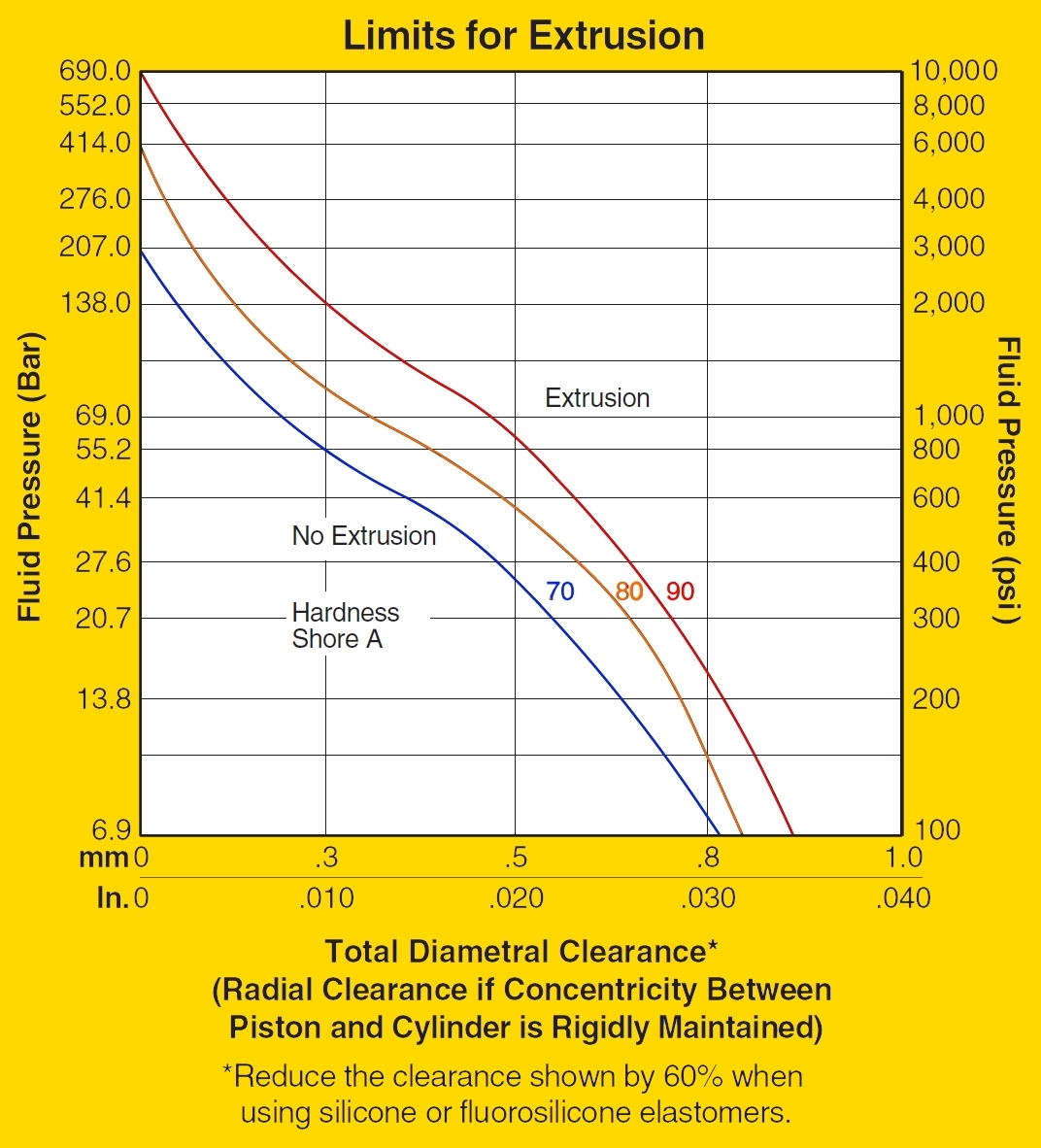

Technical handbook o rings o ring hardness the hardness of an o ring is important for several reasons.

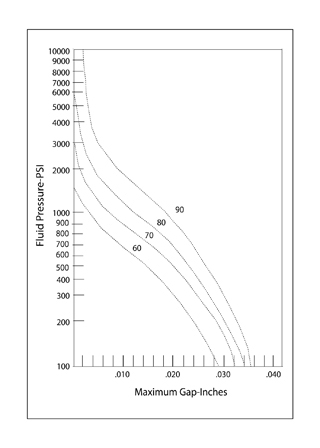

When identifying the right o ring for your sealing needs finding the right material and ensuring the type of hardness is key so it can withstand high pressure and can be more resistant to impacts.

Five measurements need to be taken.

Calibration of the durometer is one per week with elastomer blocks of different hardness.

Technical handbook o rings o ring hardness the hardness of an o ring is important for several reasons.

When identifying the right o ring for your sealing needs finding the right material and ensuring the type of hardness is key so it can withstand high pressure and can be more resistant to impacts.

Durometer shore a scale is a type of measurement for rubber material hardness.

Force is 1 kg 01 kg for shore a and 5 kg 05 kg for shore d.

The higher the durometer the harder the compound.

70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o rings applications.

Durometer shore a scale is a type of measurement for rubber material hardness.

Force is 1 kg 01 kg for shore a and 5 kg 05 kg for shore d.

The higher the durometer the harder the compound.

70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o rings applications.

The tolerance on the shore a hardness is 5 for all parker compounds.

For further information check out the material selection guide which provides a compound family overview including a description of compound advantages typical temperature maximumminimum compatible fluids and material durometers.

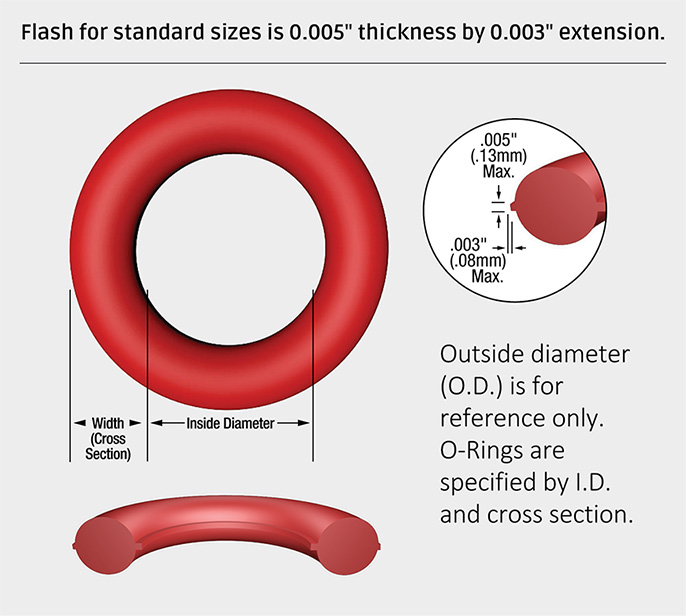

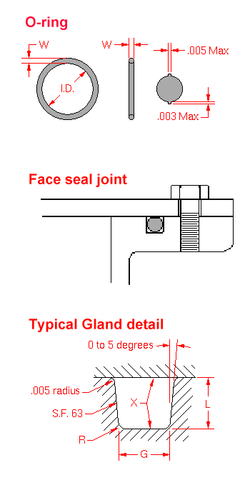

O rings are the simplest most readily.

The hardness of rubber compounds is measured by the shore a durometer.

The tolerance on the shore a hardness is 5 for all parker compounds.

For further information check out the material selection guide which provides a compound family overview including a description of compound advantages typical temperature maximumminimum compatible fluids and material durometers.

O rings are the simplest most readily.

The hardness of rubber compounds is measured by the shore a durometer.

The final value of the hardness depends on the depth of the indenter after it has been applied for 15 seconds on the material.

The higher the durometer the harder the compound.

It should be noted that there are other hardness scales used to describe elastomers b c d do o oo but these are typically not used by the rubber seal industry.

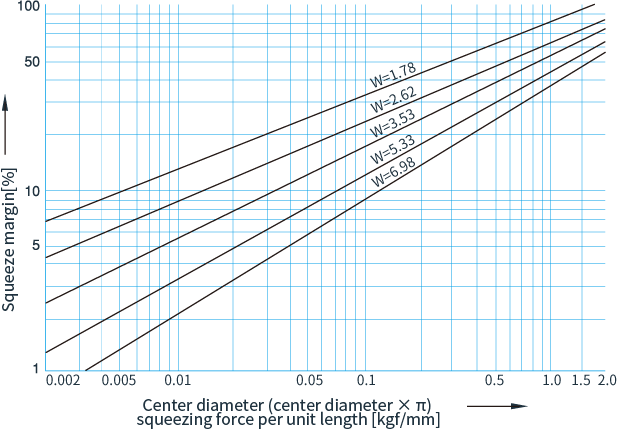

This is particularly important in low pressure seals that are not activated by fluid pressure.

The final value of the hardness depends on the depth of the indenter after it has been applied for 15 seconds on the material.

The higher the durometer the harder the compound.

It should be noted that there are other hardness scales used to describe elastomers b c d do o oo but these are typically not used by the rubber seal industry.

This is particularly important in low pressure seals that are not activated by fluid pressure.

The hardness of rubber o ring compounds are measured by the shore a durometer.

The shore a hardness measurement is called durometer.

The hardness of rubber compounds is measured by the shore a durometer.

The softer the elastomer the better the seal material conforms to the surfaces to be sealed and lower pressure is required to create a seal.

The hardness of rubber o ring compounds are measured by the shore a durometer.

The shore a hardness measurement is called durometer.

The hardness of rubber compounds is measured by the shore a durometer.

The softer the elastomer the better the seal material conforms to the surfaces to be sealed and lower pressure is required to create a seal.

70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o ring applications.

70 durometer hardness should be used whenever possible as it offers the best combination of properties for most o ring applications.