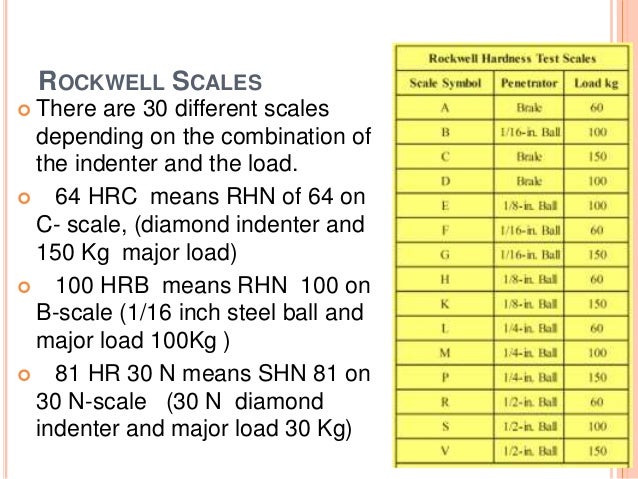

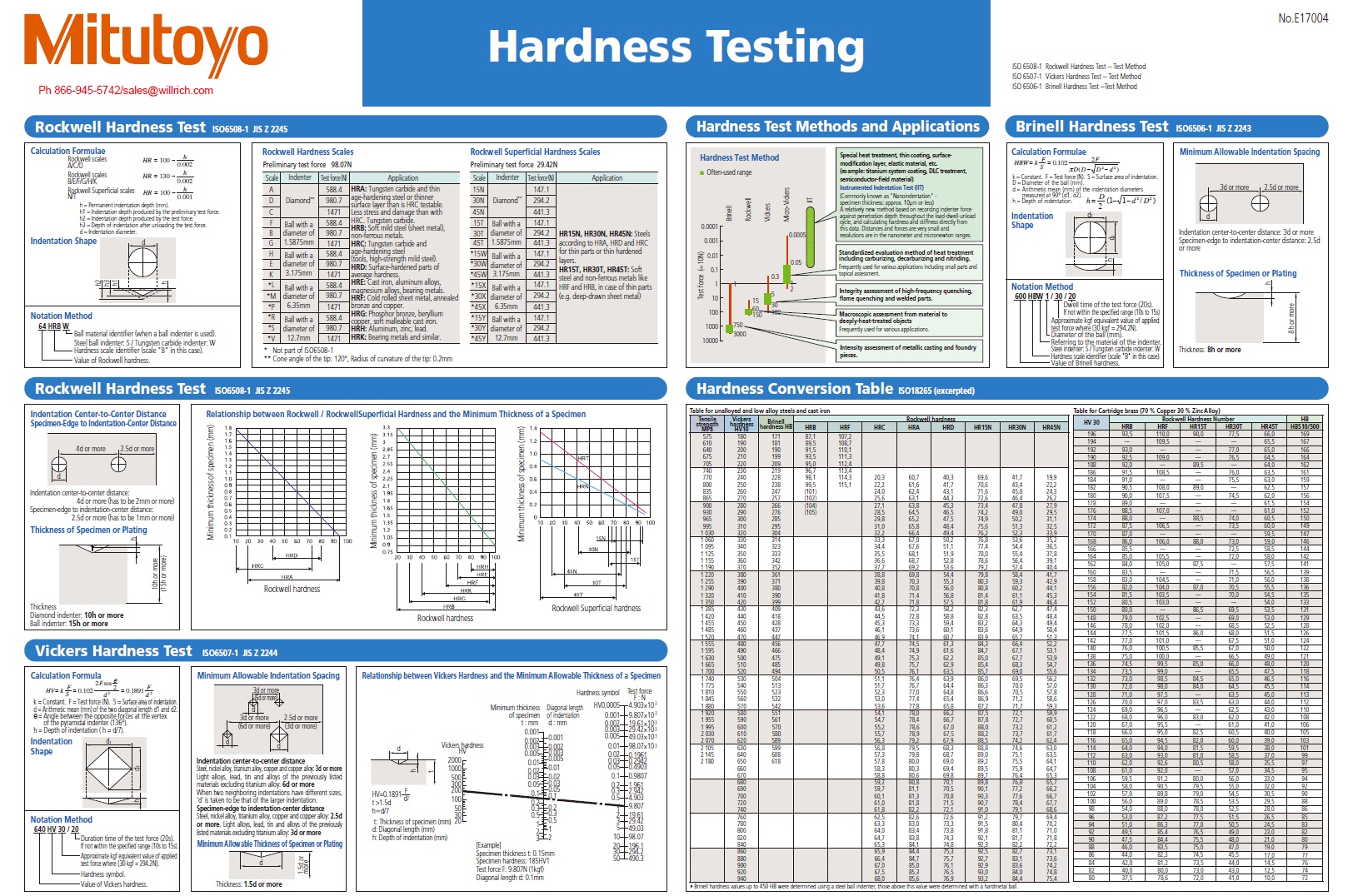

Top Rockwell Hardness Scale B To C, The rockwell hardness values are expressed as a combination of hardness number and a scale symbol representing the indenter and the minor and major loads.

Rockwell hardness scale b to c.

0 the rockwell hardness test is used to test the hardness of materials.

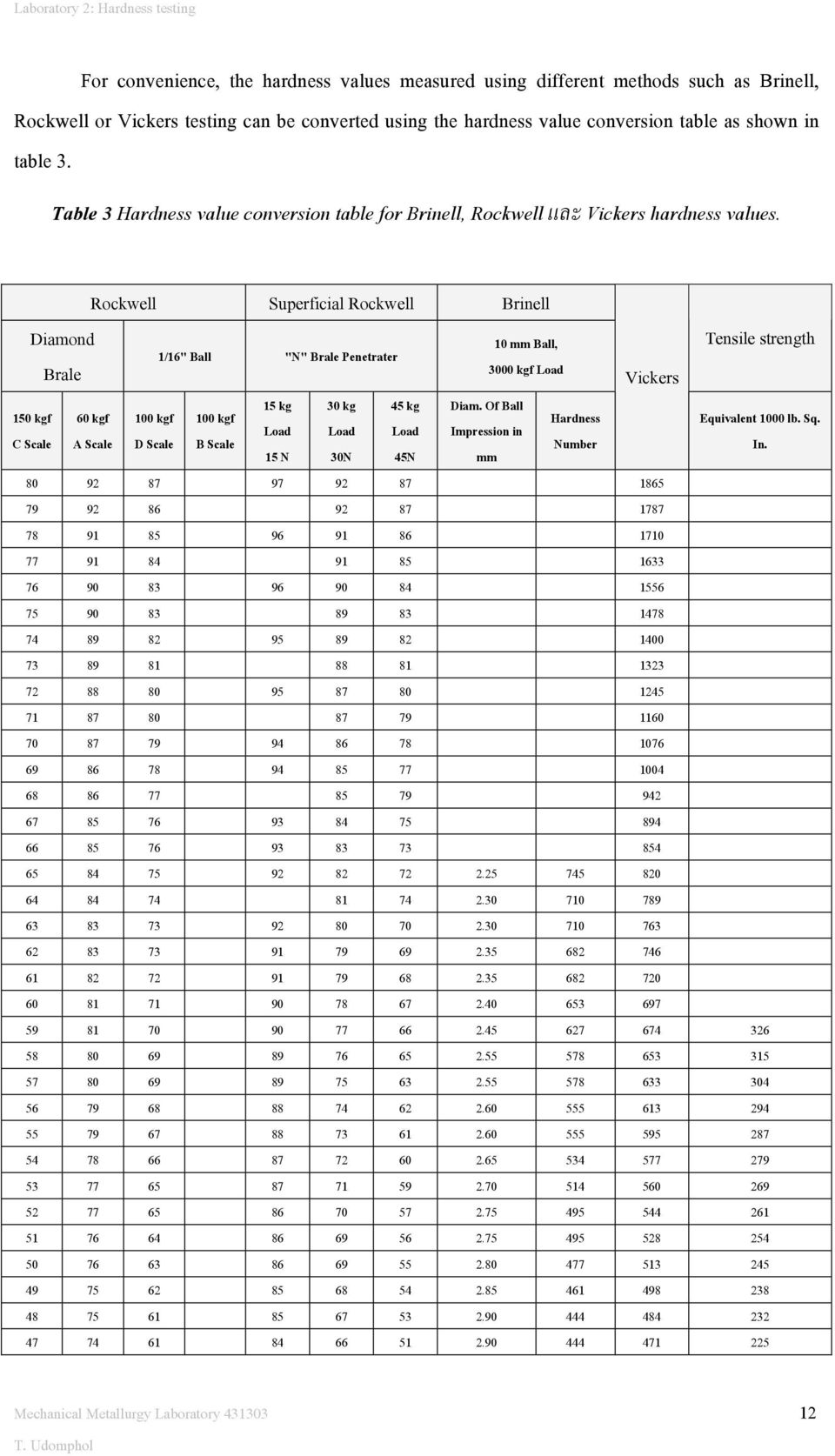

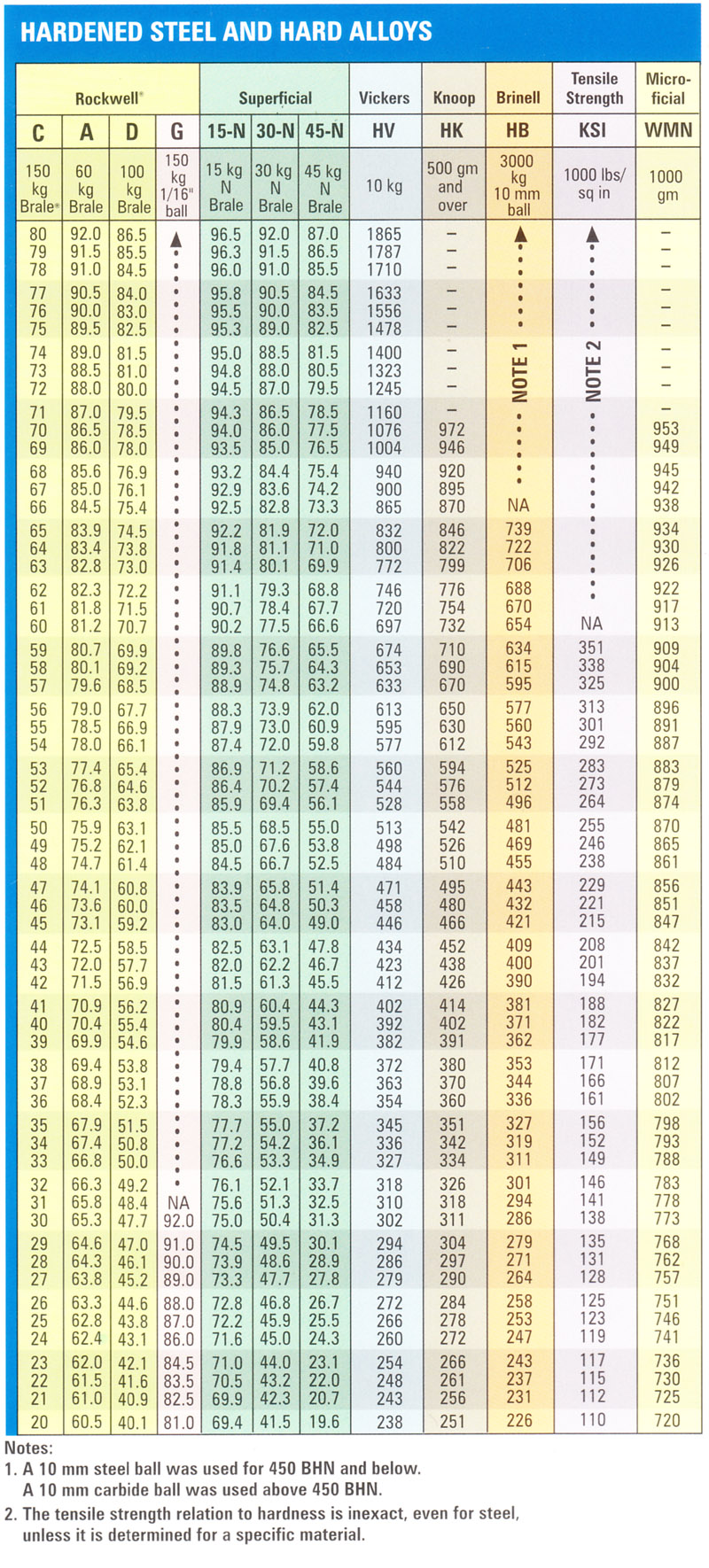

Hardness conversion chart rockwell c hardness range.

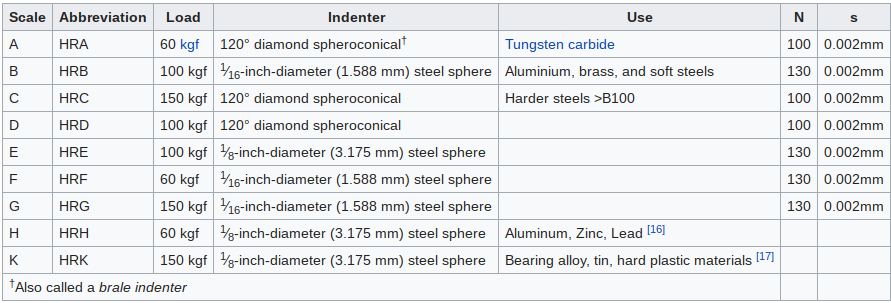

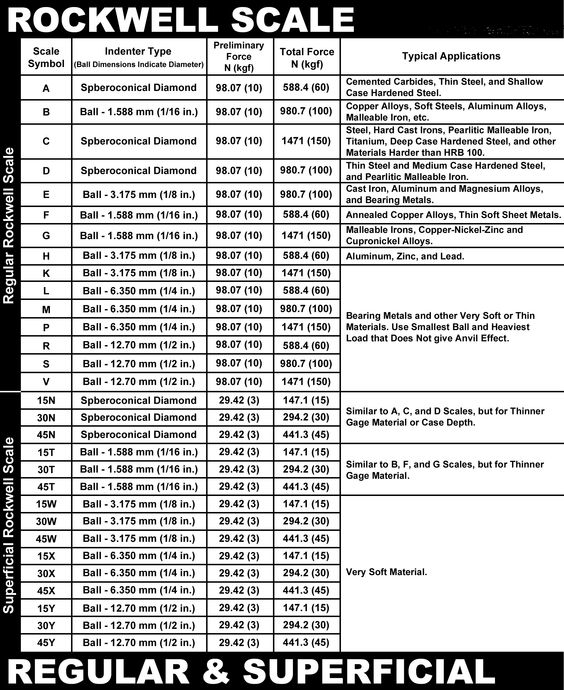

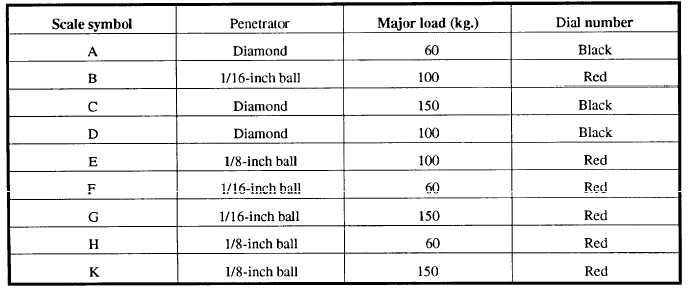

However there are multiple scales to test in and these are identified by by a letter ranging from a v each scale uses a different indenter and load to perform the test.

Rockwellthe measurement has no units.

0 the rockwell hardness test is used to test the hardness of materials.

Hardness conversion chart rockwell c hardness range.

However there are multiple scales to test in and these are identified by by a letter ranging from a v each scale uses a different indenter and load to perform the test.

Rockwellthe measurement has no units.

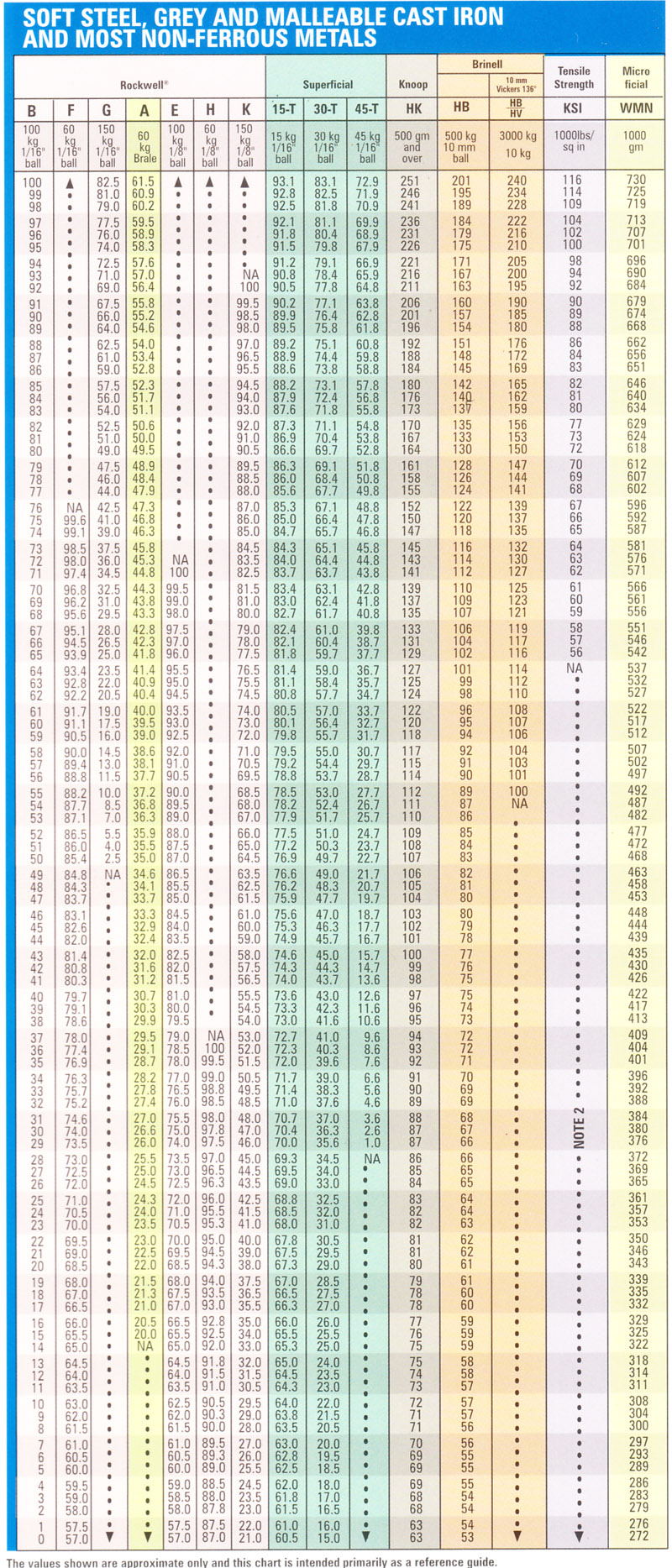

Brinell hardness rockwell b scale rockwell c scale vickers hardness number knoop hardness rockwell a scale rockwell f scale 15t scale 30t scale 45t scale approximate tensile strength.

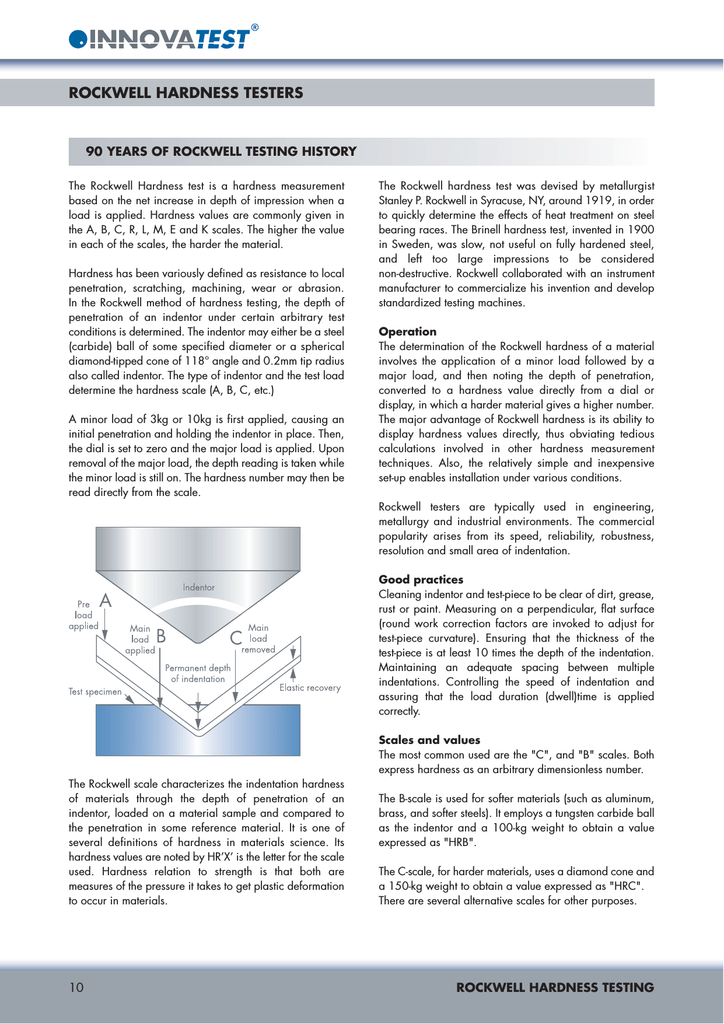

The rockwell scale is a hardness scale based on indentation hardness of a material.

The rockwell brothers were metallurgists working in a connecticut ball bearing factory back in the early 1900s.

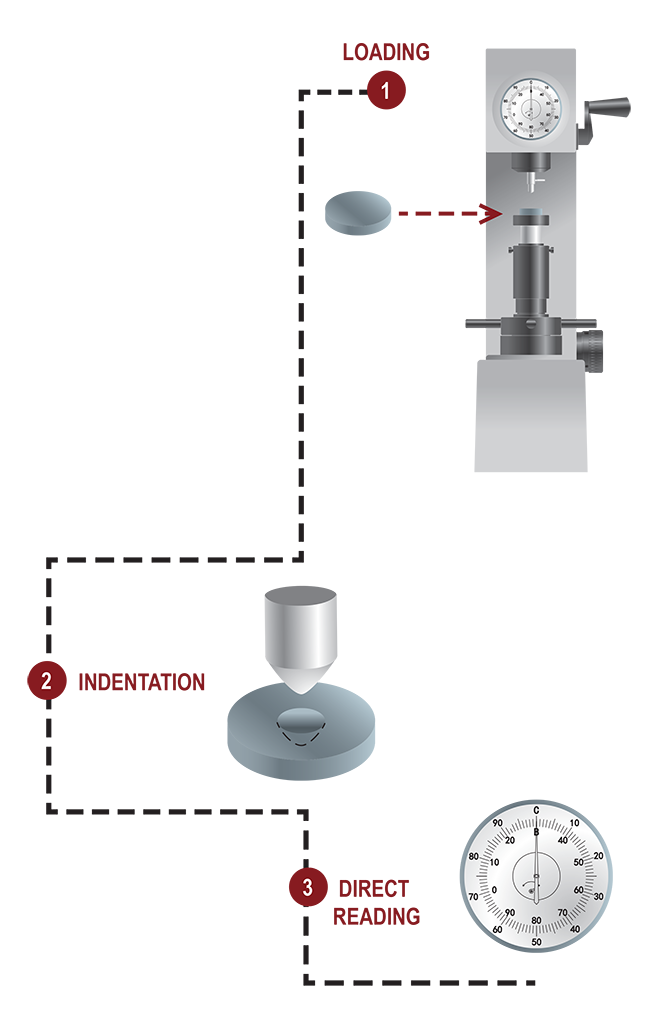

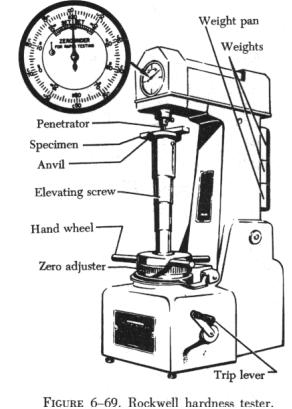

How to operate the analog rockwell hardness tester.

Brinell hardness rockwell b scale rockwell c scale vickers hardness number knoop hardness rockwell a scale rockwell f scale 15t scale 30t scale 45t scale approximate tensile strength.

The rockwell scale is a hardness scale based on indentation hardness of a material.

The rockwell brothers were metallurgists working in a connecticut ball bearing factory back in the early 1900s.

How to operate the analog rockwell hardness tester.

839 722 64.

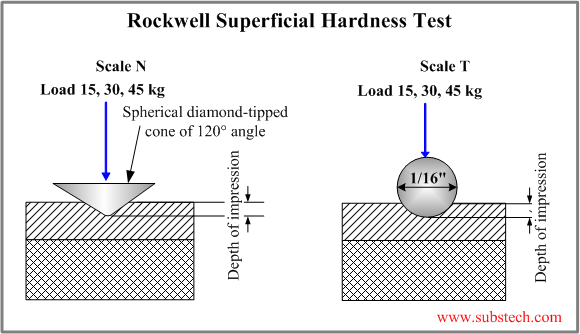

The hardness is inversely proportional to the depth of penetration.

There are different scales denoted by a single letter that use different loads or indenters.

History of the rockwell hardness scale.

839 722 64.

The hardness is inversely proportional to the depth of penetration.

There are different scales denoted by a single letter that use different loads or indenters.

History of the rockwell hardness scale.

828 688 62.

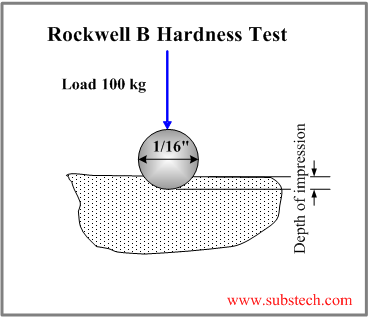

The rockwell b scale uses a 116 inch diameter ball indenter with a 100 kg load.

Tungsten carbide ball 3000 kg a scale 60 kg b scale 100 kg c scale 150 kg tensile stength approx psi 86 68 85 68 85 67 767 85.

For example 64 hrc represents the rockwell hardness number of 64 on the rockwell c scale see table 1 while 80 hrb represents a rockwell hardness number of 80 on the rockwell b scale.

828 688 62.

The rockwell b scale uses a 116 inch diameter ball indenter with a 100 kg load.

Tungsten carbide ball 3000 kg a scale 60 kg b scale 100 kg c scale 150 kg tensile stength approx psi 86 68 85 68 85 67 767 85.

For example 64 hrc represents the rockwell hardness number of 64 on the rockwell c scale see table 1 while 80 hrb represents a rockwell hardness number of 80 on the rockwell b scale.

Brinell and rockwell hardness conversion chart these conversion tables presents data in the rockwell a b c d e and f hardness range on the relationship among.

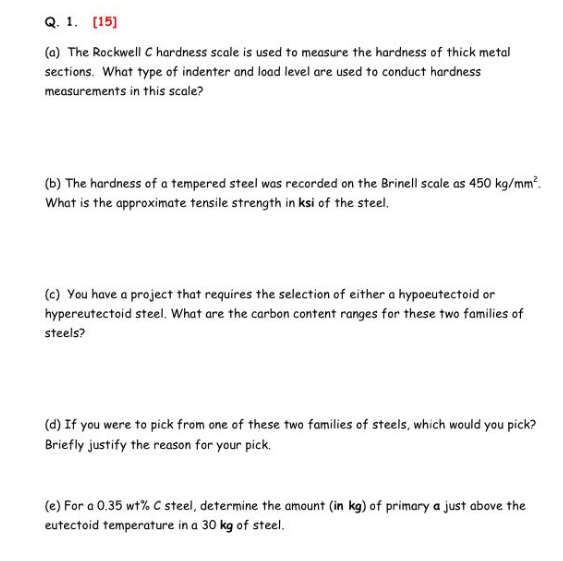

For example the rockwell c scale uses a cone shaped diamond tipped indenter with a 150 kg load.

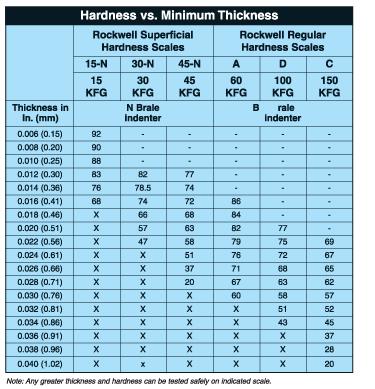

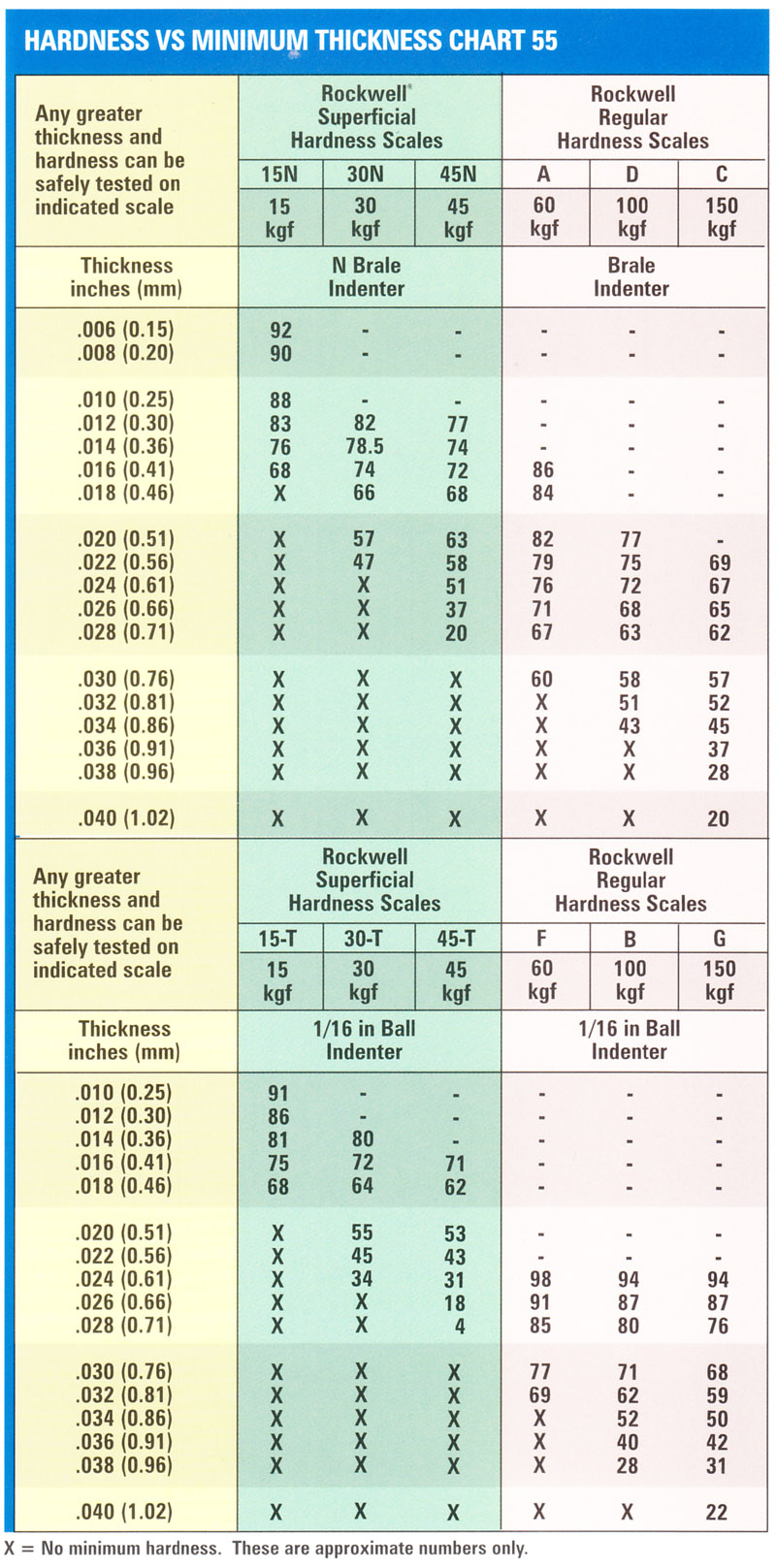

Hardness vs minimum thickness chart.

Brinell hardness rockwell hardness steel.

Brinell and rockwell hardness conversion chart these conversion tables presents data in the rockwell a b c d e and f hardness range on the relationship among.

For example the rockwell c scale uses a cone shaped diamond tipped indenter with a 150 kg load.

Hardness vs minimum thickness chart.

Brinell hardness rockwell hardness steel.

There are many rockwell hardness scales depending on the type of indenter and load used.

The rockwell hardness scale gets its name from its inventors hugh m.

The symbol is hr followed by a letter indicating one of a number of possible scales described in the table below.

The rockwell test is usually performed on metals ranging from thin steal all the way to harder metals like titanium.

There are many rockwell hardness scales depending on the type of indenter and load used.

The rockwell hardness scale gets its name from its inventors hugh m.

The symbol is hr followed by a letter indicating one of a number of possible scales described in the table below.

The rockwell test is usually performed on metals ranging from thin steal all the way to harder metals like titanium.

Hardness conversion chart rockwell b hardness range.

834 706 63.

Coating thickness gauges.

The rockwell test measuring the depth of penetration of an indenter under a large load major load compared to the penetration made by a preload minor load.

Hardness conversion chart rockwell b hardness range.

834 706 63.

Coating thickness gauges.

The rockwell test measuring the depth of penetration of an indenter under a large load major load compared to the penetration made by a preload minor load.